WO2011039686A1 - Latrepirdine oral sustained release dosage forms - Google Patents

Latrepirdine oral sustained release dosage forms Download PDFInfo

- Publication number

- WO2011039686A1 WO2011039686A1 PCT/IB2010/054309 IB2010054309W WO2011039686A1 WO 2011039686 A1 WO2011039686 A1 WO 2011039686A1 IB 2010054309 W IB2010054309 W IB 2010054309W WO 2011039686 A1 WO2011039686 A1 WO 2011039686A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- latrepirdine

- dosage form

- hours

- sustained release

- less

- Prior art date

Links

Classifications

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K31/00—Medicinal preparations containing organic active ingredients

- A61K31/33—Heterocyclic compounds

- A61K31/395—Heterocyclic compounds having nitrogen as a ring hetero atom, e.g. guanethidine or rifamycins

- A61K31/435—Heterocyclic compounds having nitrogen as a ring hetero atom, e.g. guanethidine or rifamycins having six-membered rings with one nitrogen as the only ring hetero atom

- A61K31/44—Non condensed pyridines; Hydrogenated derivatives thereof

- A61K31/4406—Non condensed pyridines; Hydrogenated derivatives thereof only substituted in position 3, e.g. zimeldine

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K45/00—Medicinal preparations containing active ingredients not provided for in groups A61K31/00 - A61K41/00

- A61K45/06—Mixtures of active ingredients without chemical characterisation, e.g. antiphlogistics and cardiaca

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K9/00—Medicinal preparations characterised by special physical form

- A61K9/0002—Galenical forms characterised by the drug release technique; Application systems commanded by energy

- A61K9/0004—Osmotic delivery systems; Sustained release driven by osmosis, thermal energy or gas

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K9/00—Medicinal preparations characterised by special physical form

- A61K9/14—Particulate form, e.g. powders, Processes for size reducing of pure drugs or the resulting products, Pure drug nanoparticles

- A61K9/16—Agglomerates; Granulates; Microbeadlets ; Microspheres; Pellets; Solid products obtained by spray drying, spray freeze drying, spray congealing,(multiple) emulsion solvent evaporation or extraction

- A61K9/1605—Excipients; Inactive ingredients

- A61K9/1617—Organic compounds, e.g. phospholipids, fats

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K9/00—Medicinal preparations characterised by special physical form

- A61K9/14—Particulate form, e.g. powders, Processes for size reducing of pure drugs or the resulting products, Pure drug nanoparticles

- A61K9/16—Agglomerates; Granulates; Microbeadlets ; Microspheres; Pellets; Solid products obtained by spray drying, spray freeze drying, spray congealing,(multiple) emulsion solvent evaporation or extraction

- A61K9/167—Agglomerates; Granulates; Microbeadlets ; Microspheres; Pellets; Solid products obtained by spray drying, spray freeze drying, spray congealing,(multiple) emulsion solvent evaporation or extraction with an outer layer or coating comprising drug; with chemically bound drugs or non-active substances on their surface

- A61K9/1676—Agglomerates; Granulates; Microbeadlets ; Microspheres; Pellets; Solid products obtained by spray drying, spray freeze drying, spray congealing,(multiple) emulsion solvent evaporation or extraction with an outer layer or coating comprising drug; with chemically bound drugs or non-active substances on their surface having a drug-free core with discrete complete coating layer containing drug

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K9/00—Medicinal preparations characterised by special physical form

- A61K9/20—Pills, tablets, discs, rods

- A61K9/2004—Excipients; Inactive ingredients

- A61K9/2022—Organic macromolecular compounds

- A61K9/205—Polysaccharides, e.g. alginate, gums; Cyclodextrin

- A61K9/2054—Cellulose; Cellulose derivatives, e.g. hydroxypropyl methylcellulose

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K9/00—Medicinal preparations characterised by special physical form

- A61K9/20—Pills, tablets, discs, rods

- A61K9/2072—Pills, tablets, discs, rods characterised by shape, structure or size; Tablets with holes, special break lines or identification marks; Partially coated tablets; Disintegrating flat shaped forms

- A61K9/2086—Layered tablets, e.g. bilayer tablets; Tablets of the type inert core-active coat

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K9/00—Medicinal preparations characterised by special physical form

- A61K9/20—Pills, tablets, discs, rods

- A61K9/28—Dragees; Coated pills or tablets, e.g. with film or compression coating

- A61K9/2806—Coating materials

- A61K9/2833—Organic macromolecular compounds

- A61K9/286—Polysaccharides, e.g. gums; Cyclodextrin

- A61K9/2866—Cellulose; Cellulose derivatives, e.g. hydroxypropyl methylcellulose

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K9/00—Medicinal preparations characterised by special physical form

- A61K9/48—Preparations in capsules, e.g. of gelatin, of chocolate

- A61K9/50—Microcapsules having a gas, liquid or semi-solid filling; Solid microparticles or pellets surrounded by a distinct coating layer, e.g. coated microspheres, coated drug crystals

- A61K9/5005—Wall or coating material

- A61K9/5021—Organic macromolecular compounds

- A61K9/5026—Organic macromolecular compounds obtained by reactions only involving carbon-to-carbon unsaturated bonds, e.g. polyvinyl pyrrolidone, poly(meth)acrylates

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K9/00—Medicinal preparations characterised by special physical form

- A61K9/48—Preparations in capsules, e.g. of gelatin, of chocolate

- A61K9/50—Microcapsules having a gas, liquid or semi-solid filling; Solid microparticles or pellets surrounded by a distinct coating layer, e.g. coated microspheres, coated drug crystals

- A61K9/5073—Microcapsules having a gas, liquid or semi-solid filling; Solid microparticles or pellets surrounded by a distinct coating layer, e.g. coated microspheres, coated drug crystals having two or more different coatings optionally including drug-containing subcoatings

- A61K9/5078—Microcapsules having a gas, liquid or semi-solid filling; Solid microparticles or pellets surrounded by a distinct coating layer, e.g. coated microspheres, coated drug crystals having two or more different coatings optionally including drug-containing subcoatings with drug-free core

Definitions

- the invention provides sustained release formulations comprising latrepirdine or pharmaceutically acceptable salts there of.

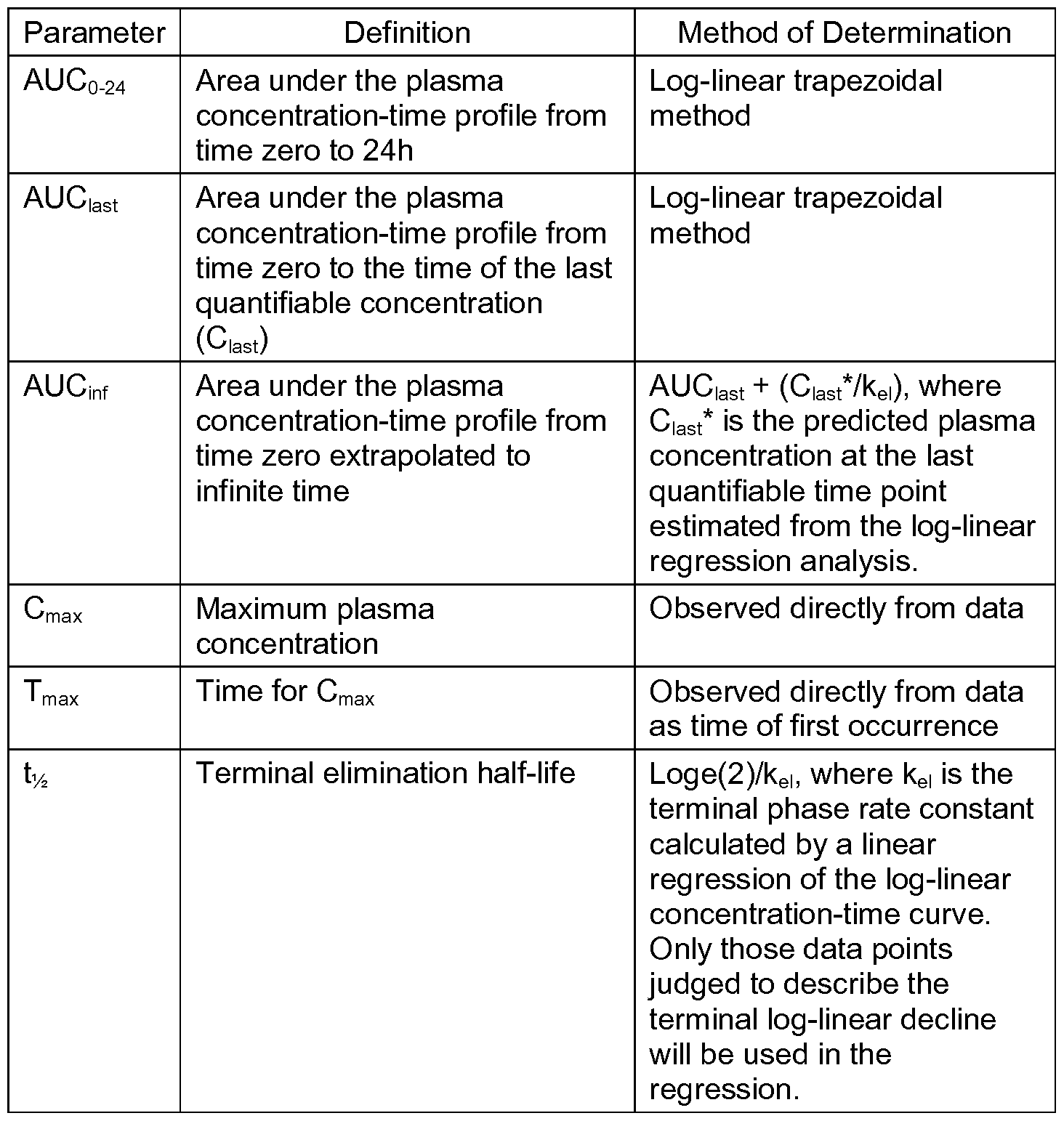

- the formulations have desirable pharmacokinetic characteristics. Examples include AUC, C max , dosage-corrected AUC, AUC/C max , Ci2 and dosage-corrected C max .

- the present invention relates to oral sustained release compositions of 2,8- dimethyl-5-[2-(6-methylpyridin-3-yl)ethyl]-3,4-dihydro-1 H-pyrido[4,3-b]indole

- latrepirdine also known in the literature as Dimebon

- AD Alzheimer's disease

- Huntington's disease a grouping of neurodegenerative diseases, and especially Alzheimer's disease (AD) and Huntington's disease.

- Latrepirdine is being commercially developed as an immediate release tablet form with doses ranging from 5 mg to 20 mg administered TID (three times a day). While the proposed commercial dosage form provides efficacious blood levels of latrepirdine to subjects, it has been observed in clinical studies that there is a substantial amount of metabolism in most subjects. The major metabolites produced are not considered to be appreciably active relative to the parent, latrepirdine. Additionally, there is a positive food effect seen in the majority of subjects. That is, the systemic absorption of the drug is enhanced when the immediate release tablets are taken with food. It is therefore desired to provide an oral sustained release dosage form containing latrepirdine that overcomes one or more of the disadvantages of an immediate release form.

- a sustained release dosage form that decreases the dosing frequency, does not undergo the degree of metabolism as the immediate release tablet dosage form, and/or that can be taken with or without food while maintaining similar to identical bioavailability in the fed or fasted state of the subject is particularly desired.

- a sustained release formulation containing a physiologically active level of drug allows blood concentrations of the drug to be maintained at or above the therapeutic concentration. Accordingly, by achieving the sustained-release characteristics of a drug it may be possible to reduce the number of dosings while providing the same or better therapeutic effects, thus potentially improving compliance. With the sustained-release characteristics of the drug, it may also be possible to avoid a rapid increase in blood plasma concentration levels immediately after administration of the drug, thus potentially reducing or eliminating adverse side effects. There is a need in the art for new drug formulations to treat Alzheimer's disease that reduce the dosing frequency which translates to greater compliance or greater efficacy. The invention is directed to these, as well as other, important ends.

- the present invention relates to oral sustained release compositions of latrepirdine for the treatment of neurodegenerative diseases, and especially Alzheimer's disease (AD) and Huntington's disease.

- Sustained release of latrepirdine may be accomplished by any means known in the pharmaceutical arts, including but not limited to the use of osmotic dosage forms, matrix dosage forms, multiparticulate dosage forms, gastric retentive dosage forms, and pulsatile dosage forms.

- latrepirdine 2,8-dimethyl-5-[2-(6-methylpyridin-3-yl)ethyl]-3,4-dihydro-1 H-pyrido[4,3- b]indole, (hereinafter referred to as "latrepirdine”) has the following structure:

- Latrepirdine should be understood, unless otherwise indicated herein, to include any pharmaceutically acceptable form of the compound. Latrepirdine may be present in crystalline or amorphous form.

- the Amet metabolite of latrepirdine is 5-[2-(2,8-dimethyl-1 ,2,3,4-tetrahydro-5/-/- pyrido[4,3-ib]indol-5-yl)ethyl]pyridine-2-carboxylic acid, herein after referred to as "A met ", and has the following structure:

- the A met metabolite is a metabolite produced in humans when latrepirdine is orally dosed.

- a met determination in human plasma samples is completed by solid phase extraction and analyzed by liquid chromatography/tandem mass spectrometry.

- Latrepirdine is useful in the treatment of various disorders, such as Alzheimer's disease, neurodegenerative disorders, Huntington's Disease and schizophrenia (see for example, U.S. Pat. No. 6,187,785; and U.S. Pat. Appl. Pub. Nos. 2007/0117835, 2007/0117834 and 2007/0225316).

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when administered orally to a cohort of subjects, having a CYP2D6 EM status, in the fasted state has a mean area under the plasma concentration versus time curve (AUC 0 -inf) ratio of latrepirdine to its A met metabolite which is greater than about 0.005 but less than 0.1.

- the dosage form has a mean area under the plasma concentration versus time curve (AUCo-inf) ratio of latrepirdine to its A met metabolite greater than about 0.01 but less than 0.1.

- the dosage form has a the mean area under the plasma concentration versus time curve (AUC 0 -inf) ratio of latrepirdine to its A met metabolite greater than about 0.04 but less than 0.1.

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when administered orally to a cohort of subjects, having a CYP2D6 EM status, in the fasted state, has a mean area under the plasma concentration versus time curve for the period following administration (AUC 0 -inf) of between 0.36 ng-hr/mL per mg of latrepirdine dosed and 12 ng-hr/mL per mg of latrepirdine dosed.

- AUC 0 -inf mean area under the plasma concentration versus time curve for the period following administration

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when administered orally to a cohort of subjects, having a CYP2D6 EM status, in the fasted state, has a mean maximum plasma concentration (C max ) of latrepirdine of less than about 0.75 ng/ml per mg of latrepirdine dosed.

- C max mean maximum plasma concentration

- the C max is less than about 0.50 ng/ml per mg of latrepirdine dosed. In yet another embodiment, the C max is less than about 0.25 ng/ml per mg of latrepirdine dosed.

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when administered orally to a cohort of subjects, having a CYP2D6 EM status, in the fasted state, has a ratio of the mean area under the latrepirdine plasma concentration versus time curve (AUC 0 -i nf ) to the mean maximum latrepirdine plasma concentration (C max ) of greater than about 10.

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when administered orally to a cohort of subjects, having a CYP2D6 EM status, as a single dose in the fasted state, has a mean area under the plasma concentration versus time curve for the period following administration (AUC 0 - in f ) of between about 0.78 ng-hr/mL per mg of latrepirdine dosed and about 1.57 ng- hr/mL per mg of latrepirdine dosed and has a mean maximum plasma concentration (C max ) of latrepirdine of less than about 0.12 ng/ml per mg of latrepirdine dosed.

- AUC 0 - in f mean area under the plasma concentration versus time curve for the period following administration

- C max mean maximum plasma concentration

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when administered orally to a cohort of subjects, having a CYP2D6 EM status, in the fasted state, has a mean latrepirdine plasma concentration twelve (12) hours post dose (d 2 ) of greater than about 0.040 ng/ml per mg of latrepirdine dosed.

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when administered orally to a cohort of subjects, having a CYP2D6 EM status, in a single dose fed / fasted crossover study, has a fed / fasted ratio of the mean area under the plasma concentration versus time curve (AUC 0 -in f ) of 0.7 to 1 .4.

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when administered orally to a cohort of subjects, having a CYP2D6 EM status, in a single dose relative bioavailability test/reference crossover study, using a 20 mg latrepirdine immediate release tablet as the reference control, displays a dose normalized relative bioavailability greater than about 1 10%.

- the immediate release control tablet formulation is the Reference treatment and the sustained release formulations are the Test treatments.

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when tested in Dissolution Test 1 , releases 80% of the latrepirdine in no less than 4 hours and no greater than 20 hours.

- a sustained release pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form, when tested in Dissolution Test 1 , releases 80% of the latrepirdine in no less than 6 hours and no greater than 20 hours.

- a sustained release pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form, when tested in Dissolution Test 1 , releases 80% of the latrepirdine in no less than 8 hours and no greater than 20 hours.

- a sustained release pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form, when tested in Dissolution Test 1 , releases 80% of the latrepirdine in no less than 12 hours and no greater than 20 hours.

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when administered orally to a cohort of subjects, having a CYP2D6 EM status, in the fasted state, has a mean area under the plasma concentration versus time curve (AUC 0 -inf) ratio of latrepirdine to its A met metabolite which is greater than about 0.005 but less than 0.1 , and when tested in Dissolution Test 1 , releases 80% of the latrepirdine in no less than 4 hours and no greater than 20 hours.

- AUC 0 -inf mean area under the plasma concentration versus time curve

- the dosage form has a mean area under the plasma concentration versus time curve (AUC 0 -inf) ratio of latrepirdine to its A met metabolite greater than about 0.01 but less than 0.1 .

- the dosage form has a the mean area under the plasma concentration versus time curve (AUCo-inf) ratio of latrepirdine to its A met metabolite greater than about 0.04 but less than 0.1.

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when administered orally to a cohort of subjects, having a CYP2D6 EM status, in the fasted state, has a mean area under the plasma concentration versus time curve (AUCo-inf) ratio of latrepirdine to its A met metabolite which is greater than about 0.005 but not greater than 0.1 , and when tested in Dissolution Test 1 , releases 80% of the latrepirdine in no less than 6 hours and no greater than 20 hours.

- AUCo-inf plasma concentration versus time curve

- the dosage form has a mean area under the plasma concentration versus time curve (AUC 0 -inf) ratio of latrepirdine to its A met metabolite greater than about 0.01 but less than 0.1 . In a further embodiment, the dosage form has a the mean area under the plasma concentration versus time curve (AUC 0 -inf) ratio of latrepirdine to its A met metabolite greater than about 0.04 but less than 0.1 .

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when administered orally to a cohort of subjects, having a CYP2D6 EM status, in the fasted state, has a mean area under the plasma concentration versus time curve (AUCo-inf) ratio of latrepirdine to its A me t metabolite which is greater than about 0.005 but not greater than 0.1 , and when tested in Dissolution Test 1 , releases 80% of the latrepirdine in no less than 8 hours and no greater than 20 hours.

- AUCo-inf plasma concentration versus time curve

- the dosage form has a mean area under the plasma concentration versus time curve (AUCo-inf) ratio of latrepirdine to its A met metabolite greater than about 0.01 but less than 0.1. In a further embodiment, the dosage form has a the mean area under the plasma concentration versus time curve (AUC 0 -inf) ratio of latrepirdine to its A met metabolite greater than about 0.04 but less than 0.1.

- AUCo-inf mean area under the plasma concentration versus time curve

- AUC 0 -inf mean area under the plasma concentration versus time curve

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when administered orally to a cohort of subjects, having a CYP2D6 EM status, in the fasted state, has a mean area under the plasma concentration versus time curve (AUC 0 -inf) ratio of latrepirdine to its A met metabolite which is greater than about 0.005 but not greater than 0.1 , and when tested in Dissolution Test 1 , releases 80% of the latrepirdine in no less than 12 hours and no greater than 20 hours.

- AUC 0 -inf mean area under the plasma concentration versus time curve

- the dosage form has a mean area under the plasma concentration versus time curve (AUC 0 -inf) ratio of latrepirdine to its A met metabolite greater than about 0.01 but less than 0.1. In a further embodiment, the dosage form has a the mean area under the plasma concentration versus time curve (AUCo-inf) ratio of latrepirdine to its A me t metabolite greater than about 0.04 but less than 0.1.

- AUC 0 -inf mean area under the plasma concentration versus time curve

- AUCo-inf mean area under the plasma concentration versus time curve

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when administered orally to a cohort of subjects, having a CYP2D6 EM status, in the fasted state, has a mean area under the plasma concentration versus time curve for the period following administration (AUC 0 -inf) of between 0.36 ng-hr/mL per mg of latrepirdine dosed and 12 ng-hr/mL per mg of latrepirdine dosed, and when tested in Dissolution Test 1 , releases 80% of the latrepirdine in no less than 4 hours and no greater than 20 hours.

- AUC 0 -inf mean area under the plasma concentration versus time curve for the period following administration

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when administered orally to a cohort of subjects, having a CYP2D6 EM status in the fasted state, has a mean area under the plasma concentration versus time curve for the period following administration (AUC 0 -inf) of between 0.36 ng-hr/mL per mg of latrepirdine dosed and 12 ng-hr/mL per mg of latrepirdine dosed, and when tested in Dissolution Test 1 , releases 80% of the latrepirdine in no less than 6 hours and no greater than 20 hours.

- AUC 0 -inf mean area under the plasma concentration versus time curve for the period following administration

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when administered orally to a cohort of subjects, having a CYP2D6 EM status, in the fasted state, has a mean area under the plasma concentration versus time curve for the period following administration (AUC 0 -inf) of between 0.36 ng-hr/mL per mg of latrepirdine dosed and 12 ng-hr/mL per mg of latrepirdine dosed, and when tested in Dissolution Test 1 , releases 80% of the latrepirdine in no less than 8 hours and no greater than 20 hours.

- AUC 0 -inf mean area under the plasma concentration versus time curve for the period following administration

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when administered orally to a cohort of subjects, having a CYP2D6 EM status, in the fasted state, has a mean area under the plasma concentration versus time curve for the period following administration (AUC 0 -in f ) of between 0.36 ng-hr/mL per mg of latrepirdine dosed and 12 ng-hr/mL per mg of latrepirdine dosed, and when tested in Dissolution Test 1 , releases 80% of the latrepirdine in no less than 12 hours and no greater than 20 hours.

- AUC 0 -in f mean area under the plasma concentration versus time curve for the period following administration

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when administered orally to a cohort of subjects, having a CYP2D6 EM status, in the fasted state, has a mean maximum plasma concentration (C max ) of latrepirdine of less than about 0.75 ng/ml per mg of latrepirdine dosed, and when tested in Dissolution Test 1 , releases 80% of the latrepirdine in no less than 4 hours and no greater than 20 hours.

- the dosage form has a C max less than about 0.50 ng/ml per mg of latrepirdine dosed.

- dosage form has a C max less than about 0.25 ng/ml per mg of latrepirdine dosed.

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when administered orally to a cohort of subjects, having a CYP2D6 EM status, in the fasted state, has a mean maximum plasma concentration (C max ) of latrepirdine of less than about 0.75 ng/ml per mg of latrepirdine dosed, and when tested in Dissolution Test 1 , releases 80% of the latrepirdine in no less than 6 hours and no greater than 20 hours.

- C max mean maximum plasma concentration

- the dosage form has a C max less than about 0.50 ng/ml per mg of latrepirdine dosed. In yet another embodiment, dosage form has a C max less than about 0.25 ng/ml per mg of latrepirdine dosed.

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when administered orally to a cohort of subjects, having a CYP2D6 EM status, in the fasted state, has a mean maximum plasma concentration (C max ) of latrepirdine of less than about 0.75 ng/ml per mg of latrepirdine dosed, and when tested in Dissolution Test 1 , releases 80% of the latrepirdine in no less than 8 hours and no greater than 20 hours.

- the dosage form has a C max less than about 0.50 ng/ml per mg of latrepirdine dosed.

- dosage form has a C max less than about 0.25 ng/ml per mg of latrepirdine dosed.

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when administered orally to a cohort of subjects, having a CYP2D6 EM status, in the fasted state, has a mean maximum plasma concentration (C max ) of latrepirdine of less than about 0.75 ng/ml per mg of latrepirdine dosed, and when tested in Dissolution Test 1 , releases 80% of the latrepirdine in no less than 12 hours and no greater than 20 hours.

- C max mean maximum plasma concentration

- the dosage form has a C max less than about 0.50 ng/ml per mg of latrepirdine dosed. In yet another embodiment, dosage form has a C max less than about 0.25 ng/ml per mg of latrepirdine dosed.

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when administered orally to a cohort of subjects, having a CYP2D6 EM status, in a single dose fed / fasted crossover study, has a fed / fasted ratio of the mean area under the plasma concentration versus time curve (AUCo-inf) of 0.7 to 1.4, and when tested in Dissolution Test 1 , releases 80% of the latrepirdine in no less than 4 hours and no greater than 20 hours.

- AUCo-inf mean area under the plasma concentration versus time curve

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when administered orally to a cohort of subjects, having a CYP2D6 EM status, in a single dose fed / fasted crossover study, has a fed / fasted ratio of the mean area under the plasma concentration versus time curve (AUC 0 -inf) of 0.7 to 1.4, and when tested in Dissolution Test 1 , releases 80% of the latrepirdine in no less than 6 hours and no greater than 20 hours.

- AUC 0 -inf mean area under the plasma concentration versus time curve

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when administered orally to a cohort of subjects, having a CYP2D6 EM status, in a single dose fed / fasted crossover study, has a fed / fasted ratio of the mean area under the plasma concentration versus time curve (AUC 0 -inf) of 0.7 to 1.4, and when tested in Dissolution Test 1 , releases 80% of the latrepirdine in no less than 8 hours and no greater than 20 hours.

- AUC 0 -inf mean area under the plasma concentration versus time curve

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when administered orally to a cohort of subjects, having a CYP2D6 EM status, in a single dose fed / fasted crossover study, has a fed / fasted ratio of the mean area under the plasma concentration versus time curve (AUC 0 -i nf ) of 0.7 to 1.4, and when tested in Dissolution Test 1 , releases 80% of the latrepirdine in no less than 12 hours and no greater than 20 hours.

- AUC 0 -i nf mean area under the plasma concentration versus time curve

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage is a sustained release form, and when tested in Dissolution Test 2, releases 80% of the latrepirdine in no less than 4 hours and no greater than 20 hours.

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage is a sustained release form, and when tested in Dissolution Test 2, releases 80% of the latrepirdine in no less than 6 hours and no greater than 20 hours.

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage is a sustained release form, and when tested in Dissolution Test 2, releases 80% of the latrepirdine in no less than 8 hours and no greater than 20 hours.

- a sustained release pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form, when tested in Dissolution Test 2, releases 80% of the latrepirdine in no less than 12 hours and no greater than 20 hours.

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when administered orally to a cohort of subjects, having a CYP2D6 EM status, in the fasted state, has a mean area under the plasma concentration versus time curve (AUC 0 -in f ) ratio of latrepirdine to its A met metabolite which is greater than about 0.005 but not greater than 0.1 , and when tested in Dissolution Test 2, releases 80% of the latrepirdine in no less than 4 hours and no greater than 20 hours.

- AUC 0 -in f mean area under the plasma concentration versus time curve

- the dosage form has a mean area under the plasma concentration versus time curve (AUC 0 -inf) ratio of latrepirdine to its A met metabolite greater than about 0.01 but less than 0.1. In a further embodiment, the dosage form has a the mean area under the plasma concentration versus time curve (AUCo-inf) ratio of latrepirdine to its A me t metabolite greater than about 0.04 but less than 0.1.

- AUC 0 -inf mean area under the plasma concentration versus time curve

- AUCo-inf mean area under the plasma concentration versus time curve

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when administered orally to a cohort of subjects, having a CYP2D6 EM status, in the fasted state, has a mean area under the plasma concentration versus time curve (AUC 0 -inf) ratio of latrepirdine to its A met metabolite which is greater than about 0.005 but not greater than 0.1 , and when tested in Dissolution Test 2, releases 80% of the latrepirdine in no less than 6 hours and no greater than 20 hours.

- AUC 0 -inf mean area under the plasma concentration versus time curve

- the dosage form has a mean area under the plasma concentration versus time curve (AUC 0 -inf) ratio of latrepirdine to its A met metabolite greater than about 0.01 but less than 0.1 . In a further embodiment, the dosage form has a the mean area under the plasma concentration versus time curve (AUC 0 -inf) ratio of latrepirdine to its A met metabolite greater than about 0.04 but less than 0.1 .

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when administered orally to a cohort of subjects, having a CYP2D6 EM status in the fasted state, has a mean area under the plasma concentration versus time curve (AUCo-inf) ratio of latrepirdine to its A met metabolite which is greater than about 0.005 but not greater than 0.1 , and when tested in Dissolution Test 2, releases 80% of the latrepirdine in no less than 8 hours and no greater than 20 hours.

- AUCo-inf mean area under the plasma concentration versus time curve

- the dosage form has a mean area under the plasma concentration versus time curve (AUCo-inf) ratio of latrepirdine to its A met metabolite greater than about 0.01 but less than 0.1. In a further embodiment, the dosage form has a the mean area under the plasma concentration versus time curve (AUCo-inf) ratio of latrepirdine to its A met metabolite greater than about 0.04 but less than 0.1.

- AUCo-inf mean area under the plasma concentration versus time curve

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when administered orally to a cohort of subjects, having a CYP2D6 EM status, in the fasted state, has a mean area under the plasma concentration versus time curve (AUC 0 -inf) ratio of latrepirdine to its A met metabolite which is greater than about 0.005 but not greater than 0.1 , and when tested in Dissolution Test 2, releases 80% of the latrepirdine in no less than 12 hours and no greater than 20 hours.

- AUC 0 -inf mean area under the plasma concentration versus time curve

- the dosage form has a mean area under the plasma concentration versus time curve (AUC 0 -i nf ) ratio of latrepirdine to its A met metabolite greater than about 0.01 but less than 0.1. In a further embodiment, the dosage form has a the mean area under the plasma concentration versus time curve (AUCo-inf) ratio of latrepirdine to its A met metabolite greater than about 0.04 but less than 0.1.

- AUC 0 -i nf mean area under the plasma concentration versus time curve

- AUCo-inf mean area under the plasma concentration versus time curve

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when administered orally to a cohort of subjects, having a CYP2D6 EM status, in the fasted state, has a mean area under the plasma concentration versus time curve for the period following administration (AUC 0 -inf) of between 0.36 ng-hr/mL per mg of latrepirdine dosed and 12 ng-hr/mL per mg of latrepirdine dosed, and when tested in Dissolution Test 2, releases 80% of the latrepirdine in no less than 4 hours and no greater than 20 hours.

- AUC 0 -inf mean area under the plasma concentration versus time curve for the period following administration

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when administered orally to a cohort of subjects, having a CYP2D6 EM status, in the fasted state, has a mean area under the plasma concentration versus time curve for the period following administration (AUC 0 -inf) of between 0.36 ng-hr/mL per mg of latrepirdine dosed and 12 ng-hr/mL per mg of latrepirdine dosed, and when tested in Dissolution Test 2, releases 80% of the latrepirdine in no less than 6 hours and no greater than 20 hours.

- AUC 0 -inf mean area under the plasma concentration versus time curve for the period following administration

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when administered orally to a cohort of subjects, having a CYP2D6 EM status, in the fasted state, has a mean area under the plasma concentration versus time curve for the period following administration (AUC 0 -inf) of between 0.36 ng-hr/mL per mg of latrepirdine dosed and 12 ng-hr/mL per mg of latrepirdine dosed, and when tested in Dissolution Test 2, releases 80% of the latrepirdine in no less than 8 hours and no greater than 20 hours.

- AUC 0 -inf mean area under the plasma concentration versus time curve for the period following administration

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when administered orally to a cohort of subjects, having a CYP2D6 EM status, in the fasted state, has a mean area under the plasma concentration versus time curve for the period following administration (AUC 0 -in f ) of between 0.36 ng-hr/mL per mg of latrepirdine dosed and 12 ng-hr/mL per mg of latrepirdine dosed, and when tested in Dissolution Test 2, releases 80% of the latrepirdine in no less than 12 hours and no greater than 20 hours.

- AUC 0 -in f mean area under the plasma concentration versus time curve for the period following administration

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when administered orally to a cohort of subjects, having a CYP2D6 EM status, in the fasted state, has a mean maximum plasma concentration (C max ) of latrepirdine of less than about 0.75 ng/ml per mg of latrepirdine dosed, and when tested in Dissolution Test 2, releases 80% of the latrepirdine in no less than 4 hours and no greater than 20 hours.

- the dosage form has a C max less than about 0.50 ng/ml per mg of latrepirdine dosed.

- dosage form has a C max less than about 0.25 ng/ml per mg of latrepirdine dosed.

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when administered orally to a cohort of subjects, having a CYP2D6 EM status, in the fasted state, has a mean maximum plasma concentration (C max ) of latrepirdine of less than about 0.75 ng/ml per mg of latrepirdine dosed, and when tested in Dissolution Test 2, releases 80% of the latrepirdine in no less than 6 hours and no greater than 20 hours.

- C max mean maximum plasma concentration

- the dosage form has a C max less than about 0.50 ng/ml per mg of latrepirdine dosed. In yet another embodiment, dosage form has a C max less than about 0.25 ng/ml per mg of latrepirdine dosed.

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when administered orally to a cohort of subjects, having a CYP2D6 EM status, in the fasted state, has a mean maximum plasma concentration (C max ) of latrepirdine of less than about 0.75 ng/ml per mg of latrepirdine dosed, and when tested in Dissolution Test 2, releases 80% of the latrepirdine in no less than 8 hours and no greater than 20 hours.

- the dosage form has a C max less than about 0.50 ng/ml per mg of latrepirdine dosed.

- dosage form has a C max less than about 0.25 ng/ml per mg of latrepirdine dosed.

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when administered orally to a cohort of subjects, having a CYP2D6 EM status, in the fasted state, has a mean maximum plasma concentration (C max ) of latrepirdine of less than about 0.75 ng/ml per mg of latrepirdine dosed, and when tested in Dissolution Test 2, releases 80% of the latrepirdine in no less than 12 hours and no greater than 20 hours.

- C max mean maximum plasma concentration

- the dosage form has a C max less than about 0.50 ng/ml per mg of latrepirdine dosed. In yet another embodiment, dosage form has a C max less than about 0.25 ng/ml per mg of latrepirdine dosed.

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when administered orally to a cohort of subjects, having a CYP2D6 EM status, in a single dose fed / fasted crossover study, has a fed / fasted ratio of the mean area under the plasma concentration versus time curve (AUC 0 -inf) of 0.7 to 1.4, and when tested in Dissolution Test 2, releases 80% of the latrepirdine in no less than 4 hours and no greater than 20 hours.

- AUC 0 -inf mean area under the plasma concentration versus time curve

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when administered orally to a cohort of subjects, having a CYP2D6 EM status, in a single dose fed / fasted crossover study, has a fed / fasted ratio of the mean area under the plasma concentration versus time curve (AUC 0 -inf) of 0.7 to 1.4, and when tested in Dissolution Test 2, releases 80% of the latrepirdine in no less than 6 hours and no greater than 20 hours.

- AUC 0 -inf mean area under the plasma concentration versus time curve

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when administered orally to a cohort of subjects, having a CYP2D6 EM status, in a single dose fed / fasted crossover study, has a fed / fasted ratio of the mean area under the plasma concentration versus time curve (AUCo-inf) of 0.7 to 1.4, and when tested in Dissolution Test 2, releases 80% of the latrepirdine in no less than 8 hours and no greater than 20 hours.

- AUCo-inf mean area under the plasma concentration versus time curve

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when administered orally to a cohort of subjects, having a CYP2D6 EM status, in a single dose fed / fasted crossover study, has a fed / fasted ratio of the mean area under the plasma concentration versus time curve (AUC 0 -inf) of 0.7 to 1.4, and when tested in Dissolution Test 2, releases 80% of the latrepirdine in no less than 12 hours and no greater than 20 hours.

- AUC 0 -inf mean area under the plasma concentration versus time curve

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when tested in Dissolution Test 1 , displays a lag phase of 1 hour in which less than 30% of the latrepirdine dose is released, followed by release of latrepirdine at a rate such that 80% or more of the total amount of latrepirdine is released in 2 hours or less.

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when administered orally to a cohort of subjects, having a CYP2D6 EM status, in the fasted state, has a mean area under the plasma concentration versus time curve (AUC 0 -inf) ratio of latrepirdine to its A met metabolite which is greater than about 0.005 but not greater than 0.1 , and when tested in Dissolution Test 1 , displays a lag phase of 1 hour in which less than 30% of the dose is released, followed by release of latrepirdine at a rate such that 80% or more of the total amount of latrepirdine is released in 2 hours or less.

- AUC 0 -inf mean area under the plasma concentration versus time curve

- the dosage form has a mean area under the plasma concentration versus time curve (AUCo-inf) ratio of latrepirdine to its A met metabolite greater than about 0.01 but less than 0.1. In a further embodiment, the dosage form has a the mean area under the plasma concentration versus time curve (AUC 0 -inf) ratio of latrepirdine to its A met metabolite greater than about 0.04 but less than 0.1.

- AUCo-inf mean area under the plasma concentration versus time curve

- AUC 0 -inf mean area under the plasma concentration versus time curve

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when administered orally to a cohort of subjects, having a CYP2D6 EM status, in the fasted state, has a mean area under the plasma concentration versus time curve for the period following administration (AUC 0 -inf) of between 0.36 ng-hr/mL per mg of latrepirdine dosed and 12 ng-hr/mL per mg of latrepirdine dosed, and when tested in Dissolution Test 1 , displays a lag phase of 1 hour in which less than 30% of the latrepirdine dose is released, followed by release of latrepirdine at a rate such that 80% or more of the total amount of latrepirdine is released in 2 hours or less.

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when administered orally to a cohort of subjects, having a CYP2D6 EM status, in the fasted state, has a mean maximum plasma concentration (C ma x) of latrepirdine of less than about 0.75 ng/ml per mg of latrepirdine dosed, and when tested in Dissolution Test 1 , displays a lag phase of 1 hour in which less than 30% of the latrepirdine dose is released, followed by release of latrepirdine at a rate such that 80% or more of the total amount of latrepirdine is released in 2 hours or less.

- C ma x mean maximum plasma concentration

- the dosage form has a Cmax less than about 0.50 ng/ml per mg of latrepirdine dosed. In yet another embodiment, dosage form has a C max less than about 0.25 ng/ml per mg of latrepirdine dosed.

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when administered orally to a cohort of subjects, having a CYP2D6 EM status, in a single dose fed / fasted crossover study, has a fed / fasted ratio of the mean area under the plasma concentration versus time curve (AUC 0 -inf) of 0.7 to 1.4, and when tested in Dissolution Test 1 , displays a lag phase of 1 hour in which less than 30% of the latrepirdine dose is released, followed by release of latrepirdine at a rate such that 80% or more of the total amount of latrepirdine is released in 2 hours or less.

- AUC 0 -inf mean area under the plasma concentration versus time curve

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when tested in Dissolution Test 2, displays a lag phase of 1 hour in which less than 30% of the latrepirdine dose is released, followed by release of latrepirdine at a rate such that 80% or more of the total amount of latrepirdine is released in 2 hours or less.

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when administered orally to a cohort of subjects, having a CYP2D6 EM status, in the fasted state, has a mean area under the plasma concentration versus time curve (AUC 0 -inf) ratio of latrepirdine to its A met metabolite which is greater than about 0.005 but not greater than 0.1 , and when tested in Dissolution Test 2, displays a lag phase of 1 hour in which less than 30% of the latrepirdine dose is released, followed by release of latrepirdine at a rate such that 80% or more of the total amount of latrepirdine is released in 2 hours or less.

- AUC 0 -inf mean area under the plasma concentration versus time curve

- the dosage form has a mean area under the plasma concentration versus time curve (AUC 0 -inf) ratio of latrepirdine to its A met metabolite greater than about 0.01 but less than 0.1 . In a further embodiment, the dosage form has a the mean area under the plasma concentration versus time curve (AUC 0 -inf) ratio of latrepirdine to its A met metabolite greater than about 0.04 but less than 0.1.

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when administered orally to a cohort of subjects, having a CYP2D6 EM status, in the fasted state, has a mean area under the plasma concentration versus time curve for the period following administration (AUC 0 -inf) of between 0.36 ng-hr/mL per mg of latrepirdine dosed and 12 ng-hr/mL per mg of latrepirdine dosed, and when tested in Dissolution Test 2, displays a lag phase of 1 hour in which less than 30% of the latrepirdine dose is released, followed by release of latrepirdine at a rate such that 80% or more of the total amount of latrepirdine is released in 2 hours or less.

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when administered orally to a cohort of subjects, having a CYP2D6 EM status, in the fasted state, has a mean maximum plasma concentration (C max ) of latrepirdine of less than about 0.75 ng/ml per mg of latrepirdine dosed, and when tested in Dissolution Test 2, displays a lag phase of 1 hour in which less than 30% of the latrepirdine dose is released, followed by release of latrepirdine at a rate such that 80% or more of the total amount of latrepirdine is released in 2 hours or less.

- C max mean maximum plasma concentration

- the dosage form has a C max less than about 0.50 ng/ml per mg of latrepirdine dosed. In yet another embodiment, dosage form has a C max less than about 0.25 ng/ml per mg of latrepirdine dosed.

- a pharmaceutical dosage form comprises and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when administered orally to a cohort of subjects, having a CYP2D6 EM status, in a single dose fed / fasted crossover study, has a fed / fasted ratio of the mean area under the plasma concentration versus time curve (AUCo-inf) of 0.7 to 1.4, and when tested in Dissolution Test 2, displays a lag phase of 1 hour in which less than 30% of the latrepirdine dose is released, followed by release of latrepirdine at a rate such that 80% or more of the total amount of latrepirdine is released in 2 hours or less.

- AUCo-inf mean area under the plasma concentration versus time curve

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when tested in Dissolution Test 1 , displays a lag phase between 0.5 and 6 hours in which less than 30% of the latrepirdine dose is released, followed by release of latrepirdine at a rate such that 80% of the total amount of latrepirdine is released in no less than 2 hours and no greater than 20 hours.

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when tested in Dissolution Test 1 , displays a lag phase of 1 hour in which less than 30% of the latrepirdine dose is released, followed by release of latrepirdine at a rate such that 80% of the total amount of latrepirdine is released in no less than 2 hours and no greater than 20 hours.

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when tested in Dissolution Test 1 , displays a lag phase of 2 hours in which less than 30% of the latrepirdine dose is released, followed by release of latrepirdine at a rate such that 80% of the total amount of latrepirdine is released in no less than 3 hours and no greater than 20 hours.

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when tested in Dissolution Test 1 , displays a lag phase of 3 hours in which less than 30% of the latrepirdine dose is released, followed by release of latrepirdine at a rate such that 80% of the total amount of latrepirdine is released in no less than 4 hours and no greater than 20 hours.

- a sustained release pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form, when tested in Dissolution Test 1 , displays a lag phase of 4 hours in which less than 30% of the latrepirdine dose is released, followed by release of latrepirdine at a rate such that 80% of the total amount of latrepirdine is released in no less than 5 hours and no greater than 20 hours.

- a sustained release pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form, when tested in Dissolution Test 1 , displays a lag phase of 5 hours in which less than 30% of the latrepirdine dose is released, followed by release of latrepirdine at a rate such that 80% of the total amount of latrepirdine is released in no less than 6 hours and no greater than 20 hours.

- a sustained release pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form, when tested in Dissolution Test 1 , displays a lag phase of 6 hours in which less than 30% of the latrepirdine dose is released, followed by release of latrepirdine at a rate such that 80% of the total amount of latrepirdine is released in no less than 7 hours and no greater than 20 hours.

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when administered orally to a cohort of subjects, having a CYP2D6 EM status, in the fasted state, has a mean area under the plasma concentration versus time curve (AUC 0 -inf) ratio of latrepirdine to its A met metabolite which is greater than about 0.005 but not greater than 0.1 , and when tested in Dissolution Test 1 , displays a lag phase between 0.5 and 6 hours in which less than 30% of the latrepirdine dose is released, followed by release of latrepirdine at a rate such that 80% of the total amount of latrepirdine is released in no less than 2 hours and no greater than 20 hours.

- AUC 0 -inf mean area under the plasma concentration versus time curve

- the dosage form has a mean area under the plasma concentration versus time curve (AUC 0 -inf) ratio of latrepirdine to its A met metabolite greater than about 0.01 but less than 0.1. In a further embodiment, the dosage form has a the mean area under the plasma concentration versus time curve (AUC 0 -inf) ratio of latrepirdine to its A met metabolite greater than about 0.04 but less than 0.1.

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when administered orally to a cohort of subjects, having a CYP2D6 EM status, in the fasted state, has a mean area under the plasma concentration versus time curve (AUCo-inf) ratio of latrepirdine to its A met metabolite which is greater than about 0.005 but not greater than 0.1 , and when tested in Dissolution Test 1 , displays a lag phase of 1 hour in which less than 30% of the latrepirdine dose is released, followed by release of latrepirdine at a rate such that 80% of the total amount of latrepirdine is released in no less than 2 hours and no greater than 20 hours.

- AUCo-inf plasma concentration versus time curve

- the dosage form has a mean area under the plasma concentration versus time curve (AUC 0 -inf) ratio of latrepirdine to its A met metabolite greater than about 0.01 but less than 0.1. In a further embodiment, the dosage form has a the mean area under the plasma concentration versus time curve (AUC 0 -inf) ratio of latrepirdine to its A met metabolite greater than about 0.04 but less than 0.1.

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when administered orally to a cohort of subjects, having a CYP2D6 EM status, in the fasted state, has a mean area under the plasma concentration versus time curve (AUC 0 -inf) ratio of latrepirdine to its A met metabolite which is greater than about 0.005 but not greater than 0.1 , and when tested in Dissolution Test 1 , displays a lag phase of 2 hours in which less than 30% of the latrepirdine dose is released, followed by release of latrepirdine at a rate such that 80% of the total amount of latrepirdine is released in no less than 3 hours and no greater than 20 hours.

- AUC 0 -inf mean area under the plasma concentration versus time curve

- the dosage form has a mean area under the plasma concentration versus time curve (AUC 0 -inf) ratio of latrepirdine to its A met metabolite greater than about 0.01 but less than 0.1. In a further embodiment, the dosage form has a the mean area under the plasma concentration versus time curve (AUCo-inf) ratio of latrepirdine to its A met metabolite greater than about 0.04 but less than 0.1.

- AUC 0 -inf mean area under the plasma concentration versus time curve

- AUCo-inf mean area under the plasma concentration versus time curve

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when administered orally to a cohort of subjects, having a CYP2D6 EM status, in the fasted state, has a mean area under the plasma concentration versus time curve (AUC 0 -inf) ratio of latrepirdine to its Amet metabolite which is greater than about 0.005 but not greater than 0.1 , and when tested in Dissolution Test 1 , displays a lag phase of 3 hours in which less than 30% of the latrepirdine dose is released, followed by release of latrepirdine at a rate such that 80% of the total amount of latrepirdine is released in no less than 4 hours and no greater than 20 hours.

- AUC 0 -inf mean area under the plasma concentration versus time curve

- the dosage form has a mean area under the plasma concentration versus time curve (AUC 0 -inf) ratio of latrepirdine to its A met metabolite greater than about 0.01 but less than 0.1 .

- the dosage form has a the mean area under the plasma concentration versus time curve (AUCo-inf) ratio of latrepirdine to its A me t metabolite greater than about 0.04 but less than 0.1 .

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when administered orally to a cohort of subjects, having a CYP2D6 EM status, in the fasted state, has a mean area under the plasma concentration versus time curve (AUCo-inf) ratio of latrepirdine to its A met metabolite which is greater than about 0.005 but not greater than 0.1 , and when tested in Dissolution Test 1 , displays a lag phase of 4 hours in which less than 30% of the latrepirdine dose is released, followed by release of latrepirdine at a rate such that 80% of the total amount of latrepirdine is released in no less than 5 hours and no greater than 20 hours.

- AUCo-inf plasma concentration versus time curve

- the dosage form has a mean area under the plasma concentration versus time curve (AUC 0 -inf) ratio of latrepirdine to its A met metabolite greater than about 0.01 but less than 0.1. In a further embodiment, the dosage form has a the mean area under the plasma concentration versus time curve (AUC 0 -inf) ratio of latrepirdine to its A met metabolite greater than about 0.04 but less than 0.1.

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when administered orally to a cohort of subjects, having a CYP2D6 EM status, in the fasted state, has a mean area under the plasma concentration versus time curve (AUC 0 -inf) ratio of latrepirdine to its A met metabolite which is greater than about 0.005 but not greater than 0.1 , and when tested in Dissolution Test 1 , displays a lag phase of 5 hours in which less than 30% of the latrepirdine dose is released, followed by release of latrepirdine at a rate such that 80% of the total amount of latrepirdine is released in no less than 6 hours and no greater than 20 hours.

- AUC 0 -inf mean area under the plasma concentration versus time curve

- the dosage form has a mean area under the plasma concentration versus time curve (AUC 0 -inf) ratio of latrepirdine to its A met metabolite greater than about 0.01 but less than 0.1. In a further embodiment, the dosage form has a the mean area under the plasma concentration versus time curve (AUCo-inf) ratio of latrepirdine to its A met metabolite greater than about 0.04 but less than 0.1.

- AUC 0 -inf mean area under the plasma concentration versus time curve

- AUCo-inf mean area under the plasma concentration versus time curve

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when administered orally to a cohort of subjects, having a CYP2D6 EM status, in the fasted state, has a mean area under the plasma concentration versus time curve (AUC 0 -inf) ratio of latrepirdine to its A met metabolite which is greater than about 0.005 but not greater than 0.1 , and when tested in Dissolution Test 1 , displays a lag phase of 6 hours in which less than 30% of the latrepirdine dose is released, followed by release of latrepirdine at a rate such that 80% of the total amount of latrepirdine is released in no less than 7 hours and no greater than 20 hours.

- AUC 0 -inf mean area under the plasma concentration versus time curve

- the dosage form has a mean area under the plasma concentration versus time curve (AUC 0 -inf) ratio of latrepirdine to its A met metabolite greater than about 0.01 but less than 0.1. In a further embodiment, the dosage form has a the mean area under the plasma concentration versus time curve (AUCo-inf) ratio of latrepirdine to its A me t metabolite greater than about 0.04 but less than 0.1.

- AUC 0 -inf mean area under the plasma concentration versus time curve

- AUCo-inf mean area under the plasma concentration versus time curve

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when administered orally to a cohort of subjects, having a CYP2D6 EM status, in the fasted state, has a mean area under the plasma concentration versus time curve for the period following administration (AUCo- inf) of between 0.36 ng-hr/mL per mg of latrepirdine dosed and 12 ng-hr/mL per mg of latrepirdine dosed, and when tested in Dissolution Test 1 , displays a lag phase between 0.5 and 6 hours in which less than 30% of the latrepirdine dose is released, followed by release of latrepirdine at a rate such that 80% of the total amount of latrepirdine is released in no less than 2 hours and no greater than 20 hours.

- AUCo- inf administration

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when administered orally to a cohort of subjects, having a CYP2D6 EM status, in the fasted state, has a mean area under the plasma concentration versus time curve for the period following administration (AUC 0 -i n f) of between 0.36 ng-hr/mL per mg of latrepirdine dosed and 12 ng-hr/mL per mg of latrepirdine dosed, and when tested in Dissolution Test 1 , displays a lag phase of 1 hour in which less than 30% of the latrepirdine dose is released, followed by release of latrepirdine at a rate such that 80% of the total amount of latrepirdine is released in no less than 2 hours and no greater than 20 hours.

- AUC 0 -i n f mean area under the plasma concentration versus time curve for the period following administration

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when administered orally to a cohort of subjects, having a CYP2D6 EM status, in the fasted state, has a mean area under the plasma concentration versus time curve for the period following administration (AUCo-inf) of between 0.36 ng-hr/mL per mg of latrepirdine dosed and 12 ng-hr/mL per mg of latrepirdine dosed, and when tested in Dissolution Test 1 , displays a lag phase of 2 hours in which less than 30% of the latrepirdine dose is released, followed by release of latrepirdine at a rate such that 80% of the total amount of latrepirdine is released in no less than 3 hours and no greater than 20 hours.

- AUCo-inf administration

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when administered orally to a cohort of subjects, having a CYP2D6 EM status, in the fasted state, has a mean area under the plasma concentration versus time curve for the period following administration (AUC 0 -inf) of between 0.36 ng-hr/mL per mg of latrepirdine dosed and 12 ng-hr/mL per mg of latrepirdine dosed, and when tested in Dissolution Test 1 , displays a lag phase of 3 hours in which less than 30% of the latrepirdine dose is released, followed by release of latrepirdine at a rate such that 80% of the total amount of latrepirdine is released in no less than 4 hours and no greater than 20 hours.

- AUC 0 -inf mean area under the plasma concentration versus time curve for the period following administration

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when administered orally to a cohort of subjects, having a CYP2D6 EM status, in the fasted state, has a mean area under the plasma concentration versus time curve for the period following administration (AUC 0 -inf) of between 0.36 ng-hr/mL per mg of latrepirdine dosed and 12 ng-hr/mL per mg of latrepirdine dosed, and when tested in Dissolution Test 1 , displays a lag phase of 4 hours in which less than 30% of the latrepirdine dose is released, followed by release of latrepirdine at a rate such that 80% of the total amount of latrepirdine is released in no less than 5 hours and no greater than 20 hours.

- AUC 0 -inf mean area under the plasma concentration versus time curve for the period following administration

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when administered orally to a cohort of subjects, having a CYP2D6 EM status, in the fasted state, has a mean area under the plasma concentration versus time curve for the period following administration (AUC 0 -inf) of between 0.36 ng-hr/mL per mg of latrepirdine dosed and 12 ng-hr/mL per mg of latrepirdine dosed, and when tested in Dissolution Test 1 , displays a lag phase of 5 hours in which less than 30% of the latrepirdine dose is released, followed by release of latrepirdine at a rate such that 80% of the total amount of latrepirdine is released in no less than 6 hours and no greater than 20 hours.

- AUC 0 -inf mean area under the plasma concentration versus time curve for the period following administration

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when administered orally to a cohort of subjects, having a CYP2D6 EM status, in the fasted state, has a mean area under the plasma concentration versus time curve for the period following administration (AUC nf ) of between 0.36 ng-hr/mL per mg of latrepirdine dosed and 12 ng-hr/mL per mg of latrepirdine dosed, and when tested in Dissolution Test 1 , displays a lag phase of 6 hours in which less than 30% of the latrepirdine dose is released, followed by release of latrepirdine at a rate such that 80% of the total amount of latrepirdine is released in no less than 7 hours and no greater than 20 hours.

- AUC nf mean area under the plasma concentration versus time curve for the period following administration

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when administered orally to a cohort of subjects, having a CYP2D6 EM status, in the fasted state, has a mean maximum plasma concentration (C max ) of latrepirdine of less than about 0.75 ng/ml per mg of latrepirdine dosed, and when tested in Dissolution Test 1 , displays a lag phase between 0.5 and 6 hours in which less than 30% of the latrepirdine dose is released, followed by release of latrepirdine at a rate such that 80% of the total amount of latrepirdine is released in no less than 2 hours and no greater than 20 hours.

- C max mean maximum plasma concentration

- the dosage form has a C max less than about 0.50 ng/ml per mg of latrepirdine dosed. In yet another embodiment, dosage form has a C max less than about 0.25 ng/ml per mg of latrepirdine dosed.

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when administered orally to a cohort of subjects, having a CYP2D6 EM status, in the fasted state, has a mean maximum plasma concentration (C max ) of latrepirdine of less than about 0.75 ng/ml per mg of latrepirdine dosed, and when tested in Dissolution Test 1 , displays a lag phase of 1 hour in which less than 30% of the latrepirdine dose is released, followed by release of latrepirdine at a rate such that 80% of the total amount of latrepirdine is released in no less than 2 hours and no greater than 20 hours.

- C max mean maximum plasma concentration

- the dosage form has a C max less than about 0.50 ng/ml per mg of latrepirdine dosed. In yet another embodiment, dosage form has a C max less than about 0.25 ng/ml per mg of latrepirdine dosed.

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when administered orally to a cohort of subjects, having a CYP2D6 EM status, in the fasted state, has a mean maximum plasma concentration (Cmax) of latrepirdine of less than about 0.75 ng/ml per mg of latrepirdine dosed, and when tested in Dissolution Test 1 , displays a lag phase of 2 hours in which less than 30% of the latrepirdine dose is released, followed by release of latrepirdine at a rate such that 80% of the total amount of latrepirdine is released in no less than 3 hours and no greater than 20 hours.

- Cmax mean maximum plasma concentration

- the dosage form has a C max less than about 0.50 ng/ml per mg of latrepirdine dosed. In yet another embodiment, dosage form has a C max less than about 0.25 ng/ml per mg of latrepirdine dosed.

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when administered orally to a cohort of subjects, having a CYP2D6 EM status, in the fasted state, has a mean maximum plasma concentration (C max ) of latrepirdine of less than about 0.75 ng/ml per mg of latrepirdine dosed, and when tested in Dissolution Test 1 , displays a lag phase of 3 hours in which less than 30% of the latrepirdine dose is released, followed by release of latrepirdine at a rate such that 80% of the total amount of latrepirdine is released in no less than 4 hours and no greater than 20 hours.

- C max mean maximum plasma concentration

- the dosage form has a C max less than about 0.50 ng/ml per mg of latrepirdine dosed. In yet another embodiment, dosage form has a C max less than about 0.25 ng/ml per mg of latrepirdine dosed.

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when administered orally to a cohort of subjects, having a CYP2D6 EM status, in the fasted state, has a mean maximum plasma concentration (C max ) of latrepirdine of less than about 0.75 ng/ml per mg of latrepirdine dosed, and when tested in Dissolution Test 1 , displays a lag phase of 4 hours in which less than 30% of the latrepirdine dose is released, followed by release of latrepirdine at a rate such that 80% of the total amount of latrepirdine is released in no less than 5 hours and no greater than 20 hours.

- C max mean maximum plasma concentration

- the dosage form has a C max less than about 0.50 ng/ml per mg of latrepirdine dosed. In yet another embodiment, dosage form has a Cmax less than about 0.25 ng/ml per mg of latrepirdine dosed.

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when administered orally to a cohort of subjects, having a CYP2D6 EM status, in the fasted state, has a mean maximum plasma concentration (C max ) of latrepirdine of less than about 0.75 ng/ml per mg of latrepirdine dosed, and when tested in Dissolution Test 1 , displays a lag phase of 5 hours in which less than 30% of the latrepirdine dose is released, followed by release of latrepirdine at a rate such that 80% of the total amount of latrepirdine is released in no less than 6 hours and no greater than 20 hours.

- C max mean maximum plasma concentration

- the dosage form has a C max less than about 0.50 ng/ml per mg of latrepirdine dosed. In yet another embodiment, dosage form has a C max less than about 0.25 ng/ml per mg of latrepirdine dosed.

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when administered orally to a cohort of subjects, having a CYP2D6 EM status, in the fasted state, has a mean maximum plasma concentration (C max ) of latrepirdine of less than about 0.75 ng/ml per mg of latrepirdine dosed, and when tested in Dissolution Test 1 , displays a lag phase of 6 hours in which less than 30% of the latrepirdine dose is released, followed by release of latrepirdine at a rate such that 80% of the total amount of latrepirdine is released in no less than 7 hours and no greater than 20 hours.

- C max mean maximum plasma concentration

- the dosage form has a C max less than about 0.50 ng/ml per mg of latrepirdine dosed. In yet another embodiment, dosage form has a C max less than about 0.25 ng/ml per mg of latrepirdine dosed.

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when administered orally to a cohort of subjects, having a CYP2D6 EM status, in a single dose fed / fasted crossover study, has a fed / fasted ratio of the mean area under the plasma concentration versus time curve (AUCo-inf) of 0.7 to 1.4, and when tested in Dissolution Test 1 , displays a lag phase between 0.5 and 6 hours in which less than 30% of the latrepirdine dose is released, followed by release of latrepirdine at a rate such that 80% of the total amount of latrepirdine is released in no less than 2 hours and no greater than 20 hours.

- AUCo-inf mean area under the plasma concentration versus time curve

- a pharmaceutical dosage form comprises latrepirdine and a pharmaceutically acceptable carrier, wherein said dosage form is a sustained release dosage form, and when administered orally to a cohort of subjects, having a CYP2D6 EM status, in a single dose fed / fasted crossover study, has a fed / fasted ratio of the mean area under the plasma concentration versus time curve (AUCo-inf) of 0.7 to 1.4, and when tested in Dissolution Test 1 , displays a lag phase of 1 hour in which less than 30% of the latrepirdine dose is released, followed by release of latrepirdine at a rate such that 80% of the total amount of latrepirdine is released in no less than 2 hours and no greater than 20 hours.

- AUCo-inf mean area under the plasma concentration versus time curve