Abstract

The non-uniform shape and diverse dimensions exert a substantial influence on the distribution of forces within the ballast, hence affecting its bearing capacity. The objective of this work was to investigate the interrelated impact of particle shape and size on ballast strength, and then construct a prediction model that could estimate the chance of ballast crushing. For these purposes, both three-dimensional scanning and single-particle compression tests were undertaken. The morphology of ballast particles at various scales was comprehensively characterized by computing diverse parameters based on the scanning results. The present study systematically assessed the impact of size, overall shape and roundness on particle crushing behavior and parameters. Then a novel approach was introduced to calculate characteristic strength, taking into account the influence of particle morphology. A ballast crushing probability distribution model was established, which incorporated the Weibull model. The anticipation of ballast crushing probabilities can be achieved within this framework by analyzing particle size and morphology parameters. At last, the actual crushing probabilities were compared to the predicted probabilities for a sample of 50 randomly chosen ballasts. The results revealed that 80% of the particles displayed a deviation of less than 10%, which proved the accuracy of the applied method.

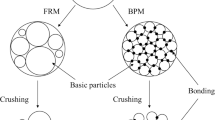

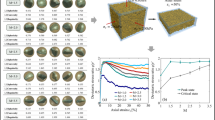

Graphical abstract

Similar content being viewed by others

Data availability

Data will be made available on request.

References

Indraratna, B., Salim, W., Rujikiatkamjorn, C.: Advanced Rail Geotechnology—Ballasted Track. CRC Press/Balkema, Boca Raton (2011)

Indraratna, B., Ngo, T., Rujikiatkamjorn, C.: Performance of ballast influenced by deformation and degradation: laboratory testing and numerical modeling. Int. J. Geomech. 20, 04019138 (2020). https://doi.org/10.1061/(ASCE)GM.1943-5622.0001515

Lim, W.L., McDowell, G.R., Collop, A.C.: The application of Weibull statistics to the strength of railway ballast. Granul. Matter 6, 229–237 (2004). https://doi.org/10.1007/s10035-004-0180-z

Zhou, W., Yang, L., Ma, G., Chang, X., Lai, Z., Xu, K.: DEM analysis of the size effects on the behavior of crushable granular materials. Granul. Matter 18, 64 (2016). https://doi.org/10.1007/s10035-016-0656-7

Huang, Q.S., Zhou, W., Ma, G., Ng, T.T., Xu, K.: Experimental and numerical investigation of Weibullian behavior of grain crushing strength. Geosci. Front. 11, 401–411 (2020). https://doi.org/10.1016/j.gsf.2019.07.007

Zhang, X., Liu, X., Xu, Y., Wang, G., Zang, M.: Fragmentation modes of single coral particles under uniaxial compression: Microstructural insights. Constr Build Mater. 344, 128186 (2022). https://doi.org/10.1016/j.conbuildmat.2022.128186

Xiao, Y., Sun, Z., Desai, C.S., Meng, M.: Strength and surviving probability in grain crushing under acidic erosion and compression. Int. J. Geomech. 19, 04019123 (2019). https://doi.org/10.1061/(ASCE)GM.1943-5622.0001508

Yan, W.M., Shi, Y.: Evolution of grain grading and characteristics in repeatedly reconstituted assemblages subject to one-dimensional compression. Geotech Lett. 4, 223–229 (2014). https://doi.org/10.1680/geolett.14.00039

Xiao, Y., Liu, H., Chen, Y., Jiang, J.: Strength and deformation of rockfill material based on large-scale triaxial compression tests. I: influences of density and pressure. J. Geotech. Geoenviron. 140, 04014070 (2014). https://doi.org/10.1061/(ASCE)GT.1943-5606.0001176

Liu, J.X., Sysyn, M., Liu, Z.Y., Kou, L., Wang, P.: Studying the strengthening effect of railway ballast in the direct shear test due to insertion of middle-size ballast particles. J. Appl. Comput. Mech. 8, 1387–1397 (2022). https://doi.org/10.22055/jacm.2022.40206.3537

Kalasin, T., Khamchan, C., Aoddej, A.: Effects of particle size and soil bed on the shear strength of materials in the direct shear test. Period Polytech.-Civ. (2022). https://doi.org/10.3311/PPci.20416

Xiao, Y., Meng, M.Q., Daouadji, A., Chen, Q.S., Wu, Z.J., Jiang, X.: Effects of particle size on crushing and deformation behaviors of rockfill materials. Geosci. Front. 11, 375–388 (2020). https://doi.org/10.1016/j.gsf.2018.10.010

Zhou, H.J., Ma, G., Yuan, W., Wei, Z.: Size effect on the crushing strengths of rock particles. Rock Soil Mech. 38, 2425–2433 (2017). https://doi.org/10.16285/j.rsm.2017.08.032

Zhao, X.L., Zhu, J.A., Jia, Y., Colliat, J.B., Bian, H.B., Zhang, Q.: Experimental and numerical study of size effects on the crushing strength of rockfill particles. Int. J. Numer. Anal. Met. 46, 2060–2086 (2022). https://doi.org/10.1002/nag.3379

Wang, Y.H., Ma, G., Mei, J.Z., Zou, Y.X., Zhang, D.R., Zhou, W., Cao, X.X.: Machine learning reveals the influences of grain morphology on grain crushing strength. Acta Geotech. 16, 3617–3630 (2021). https://doi.org/10.1007/s11440-021-01270-1

Zheng, S.F., Liu, Y., Zhang, N., Li, X., Gao, L.: Experimental studies on shape and size effects on particle breakage of railway ballast. Transp. Geotech. 37, 100883 (2022). https://doi.org/10.1016/j.trgeo.2022.100883

Aman, S., Tomas, J., Kalman, H.: Breakage probability of irregularly shaped particles. Chem. Eng. Sci. 65, 1503–1512 (2010). https://doi.org/10.1016/j.ces.2009.10.016

Kim, J., Park, B.S., Woo, S.I., Choi, Y.T.: Evaluation of ballasted-track condition based on aggregate-shape characterization. Constr. Build. Mater. 232, 117082 (2020). https://doi.org/10.1016/j.conbuildmat.2019.117082

Xu, Y., Yu, W.Y., Qie, L.C., Wang, H., Ning, N.: Analysis of influence of ballast shape on abrasion resistance using discrete element method. Constr. Build. Mater. 273, 121708 (2021). https://doi.org/10.1016/j.conbuildmat.2020.121708

Guo, Y.L., Markine, V., Song, J.N., Jing, G.Q.: Ballast degradation: effect of particle size and shape using Los Angeles Abrasion test and image analysis. Constr. Build. Mater. 169, 414–424 (2018). https://doi.org/10.1016/J.CONBUILDMAT.2018.02.170

Jing, G.Q., Ji, Y.M., Qiang, W.L., Zhang, R.: Experimental and numerical study on ballast flakiness and elongation index by direct shear test. Int. J. Geomech. 20, 04020169 (2020). https://doi.org/10.1061/(ASCE)GM.1943-5622.0001791

Danesh, A., Mirghasemi, A.A., Palassi, M.: Evaluation of particle shape on direct shear mechanical behavior of ballast assembly using discrete element method (DEM). Transp. Geotech. 23, 100357 (2020). https://doi.org/10.1016/j.trgeo.2020.100357

Wadell, H.: Volume, shape, and roundness of rock particles. J. Geol. 40, 443–451 (1932)

Blott, S.J., Pye, K.: Particle shape: a review and new methods of characterization and classification. Sedimentology 55, 31–63 (2008). https://doi.org/10.1111/j.1365-3091.2007.00892.x

Zhou, B., Wang, J., Wang, H.: Three-dimensional sphericity, roundness and fractal dimension of sand particles. Geotechnique 68, 18–30 (2018). https://doi.org/10.1680/jgeot.16.P.207

Weibull, G.W.: A statistical distribution function of wide applicability. Appl. Mech. 18, 293–297 (1951)

Al-Saoudi, N.K.S., Hassan, K.H.: Evaluation of indirect tensile strength of track ballast using weibull statistics. Geotech. Geol. Eng. 30, 1097–1102 (2012). https://doi.org/10.1007/s10706-012-9525-2

Mcdowell, G.R., Amon, A.: The application of Weibull statistics to the fracture of soil particles. Soils Found. 40, 133–141 (2000). https://doi.org/10.3208/sandf.40.5_133

Krumbein, W.C.: Measurement and geological significance of shape and roundness of sedimentary particles. J. Sed. Petrol. 11, 64–72 (1941). https://doi.org/10.1306/D42690F3-2B26-11D7-8648000102C1865D

Corey, A.T.: Influence of Shape on Fall Velocity of Sand Grains. Colorado A&M College, Colorado (1949)

Sneed, E.D., Folk, R.L.: Pebbles in the lower colorado river, Texas a study in particle morphogenesis. J. Geol. 66, 114–150 (1958). https://doi.org/10.2307/30058239

Aschenbrenner, B.C.: A new method of expressing particle sphericity. J. Sediment. Res. 26, 15–31 (1956)

Nie, Z.H., Liang, Z.Y., Wang, X.: A three-dimensional particle roundness evaluation method. Granul. Matter 20, 1–11 (2018). https://doi.org/10.1007/s10035-018-0802-5

Hayakawa, Y., Oguchi, T.: Evaluation of gravel sphericity and roundness based on surface-area measurement with a laser scanner. Comput. Geosci.-UK 31, 735–741 (2005). https://doi.org/10.1016/j.cageo.2005.01.004

Cornea, N.D., Silver, D., Min, P.: Curve-skeleton properties, applications, and algorithms. IEEE Trans. Vis. Comput. Graph. 13, 530–548 (2007). https://doi.org/10.1109/TVCG.2007.1002

Zheng, J.X., He, H.T., Alimohammadi, H.: Three-dimensional Wadell roundness for particle angularity characterization of granular soils. Acta Geotech. 16, 133–149 (2021). https://doi.org/10.1007/s11440-020-01004-9

Darlington, W.J., Ranjith, P.G., Choi, S.K.: The effect of specimen size on strength and other properties in laboratory testing of rock and rock-like cementitious brittle materials. Rock Mech. Rock Eng. 44, 513–529 (2011). https://doi.org/10.1007/s00603-011-0161-6

Yu, Q.L., Zhu, W.C., Ranjith, P.G., Shao, S.S.: Numerical simulation and interpretation of the grain size effect on rock strength. Geomech. Geophys. Geo-resour. 4, 157–173 (2018). https://doi.org/10.1007/s40948-018-0080-z

Skipochka, S., Krukovskyi, O., Palamarchuk, T., Prokhorets, L.: On the methodology for considering scale effect of rock strength. Min. Miner. Deposits. 14, 24–30 (2020). https://doi.org/10.33271/mining14.04.024

Hu, G.J., Li, Y., Ma, G.: Research on the size effect of roughness on rock uniaxial compressive strength and characteristic strength. Sci. Eng. Compos. Mater. 28, 613–627 (2021). https://doi.org/10.1515/secm-2021-0058

Antonyuk, S., Tomas, E., Heinrich, S., Morl, L.: Breakage behaviour of spherical granulates by compression. Chem. Eng. Sci. 60, 4031–4044 (2005). https://doi.org/10.1016/j.ces.2005.02.038

Zhong, S., Baitalow, F., Nikrityuk, P., Gutte, H., Meyer, B.: The effect of particle size on the strength parameters of German brown coal and its chars. Fuel 125, 200–205 (2014). https://doi.org/10.1016/j.fuel.2014.02.022

Dong, J., Cheng, Y.P., Hu, B., Hao, C.M., Tu, Q.Y., Liu, Z.D.: Experimental study of the mechanical properties of intact and tectonic coal via compression of a single particle. Powder Technol. 325, 412–419 (2018). https://doi.org/10.1016/j.powtec.2017.11.029

Cheshomi, A., Mousavi, E., Ahmadi-Sheshde, E.: Evaluation of single particle loading test to estimate the uniaxial compressive strength of sandstone. J. Petrol. Sci. Eng. 135, 421–428 (2015). https://doi.org/10.1016/j.petrol.2015.09.031

Zagar, G., Pejchal, V., Kissling, M., Mortensen, A.: On the diametric compression strength test of brittle spherical particles. Eur. J. Mech. A-Solid. 72, 148–154 (2018). https://doi.org/10.1016/j.euromechsol.2018.04.016

Jaeger, J.C.: Failure of rocks under tensile conditions. Int. J. Rock Mech. Min. 4, 219–227 (1967). https://doi.org/10.1016/0148-9062(67)90046-0

Lee, D.M.: The Angles of Friction of Granular Fills. University of Cambridge, Cambridge (1992)

Scholtes, L., Donze, F.V., Khanal, M.: Scale effects on strength of geomaterials, case study: coal. J. Mech. Phys. Solids 59, 1131–1146 (2011). https://doi.org/10.1016/j.jmps.2011.01.009

Petalas, Y.G., Parsopoulos, K.E., Vrahatis, M.N.: Memetic particle swarm optimization. Ann. Oper. Res. 156, 99–127 (2007). https://doi.org/10.1007/s10479-007-0224-y

Beheshti, Z., Shamsuddin, S.M.H.: CAPSO: centripetal accelerated particle swarm optimization. Inform. Sci. 258, 54–79 (2014). https://doi.org/10.1016/j.ins.2013.08.015

van Zyl, J.P., Engelbrecht, A.P.: Set-based particle swarm optimisation: a review. Math.-Basel. 11, 2980 (2023). https://doi.org/10.3390/math11132980

Acknowledgements

This work was financially supported by National Natural Science Foundation of China (NSFC) (Grant Nos. 51878521, 51178358). The support is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Gao, R., Yuan, Z., Hu, Q. et al. Ballast crushing probability model considering the influence of particle morphology and size. Granular Matter 26, 45 (2024). https://doi.org/10.1007/s10035-024-01414-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10035-024-01414-6