Printing and Saving Instructions - Technical Learning College

Printing and Saving Instructions - Technical Learning College

Printing and Saving Instructions - Technical Learning College

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

WATER TREATMENT 303<br />

CONTINUING EDUCATION<br />

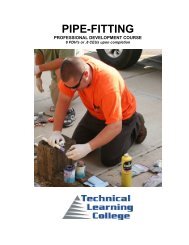

PROFESSIONAL DEVELOPMENT COURSE

WT303� 10/13/2011 TLC 2<br />

(866) 557-1746 Fax (928) 468-0675

<strong>Printing</strong> <strong>and</strong> <strong>Saving</strong> <strong>Instructions</strong><br />

The best thing to do is to download this pdf document to your<br />

computer desktop <strong>and</strong> open it with Adobe Acrobat reader.<br />

Abode Acrobat reader is a free computer software program <strong>and</strong> you<br />

can find it at Abode Acrobat’s website.<br />

You can complete the course by viewing the course materials on your<br />

computer or you can print it out. We give you permission to print this<br />

document.<br />

<strong>Printing</strong> <strong>Instructions</strong>: If you are going to print this document, this<br />

document is designed to be printed double-sided or duplexed but can<br />

be single-sided.<br />

This course booklet does not have the assignment. Please visit our<br />

website <strong>and</strong> download the assignment also.<br />

Internet Link to Assignment…<br />

http://www.abctlc.com/PDF/Treatment303ASS.pdf<br />

State Approval Listing Link, check to see if your State accepts or has<br />

pre-approved this course. Not all States are listed. Not all courses<br />

are listed. If the course is not accepted for CEU credit, we will give<br />

you the course free if you ask your State to accept it for credit.<br />

Professional Engineers: Most states will accept our courses for<br />

credit but we do not officially list the States or Agencies acceptance<br />

or approvals.<br />

State Approval Listing URL…<br />

http://www.tlch2o.com/PDF/CEU%20State%20Approvals.pdf<br />

You can obtain a printed version from TLC for an additional $79.95<br />

plus shipping charges.<br />

WT303� 10/13/2011 TLC 3<br />

(866) 557-1746 Fax (928) 468-0675

We have taught this course to over 5,000 students in a conventional classroom<br />

setting. Call <strong>and</strong> schedule a class at your facility or utilize the distance learning<br />

course to obtain your CEUs.<br />

Copyright Notice<br />

©2010 <strong>Technical</strong> <strong>Learning</strong> <strong>College</strong> (TLC). No part of this work may be reproduced or distributed in any form<br />

or by any means without TLC’s prior written approval. Permission has been sought for all images <strong>and</strong> text<br />

where we believe copyright exists <strong>and</strong> where the copyright holder is traceable <strong>and</strong> contactable. All material<br />

not credited or acknowledged is the copyright of TLC. The information in this manual is intended for<br />

educational purposes only. Most unaccredited photographs have been taken by TLC instructors or TLC<br />

students. We would be pleased to hear from any copyright holder <strong>and</strong> will make good on your work if any<br />

unintentional copyright infringements were made upon these issues being brought to our attention.<br />

Every possible effort is made to ensure all information provided in this course is accurate. All written,<br />

graphic, photographic or other material is provided for information only. Therefore, TLC accepts no<br />

responsibility or liability whatsoever for the application or misuse of any information included herein.<br />

Requests for permission to make copies should be made to the following address:<br />

TLC<br />

PO Box 420<br />

Payson, AZ 85547-0420<br />

Information in this document is subject to change without notice. TLC is not liable for errors or omissions<br />

appearing in this document.<br />

WT303� 10/13/2011 TLC 4<br />

(866) 557-1746 Fax (928) 468-0675

Contributing Editors<br />

Joseph Camerata has a BS in Management with honors (magna cum laude). He retired<br />

as a Chemist in 2006 having worked in the field of chemical, environmental, <strong>and</strong><br />

industrial hygiene sampling <strong>and</strong> analysis for 40 years. He has been a professional<br />

presenter at an EPA analytical conference at the Biosphere in Arizona <strong>and</strong> a<br />

presenter at an AWWA conference in Mesa, Arizona. He also taught safety classes at<br />

the Honeywell <strong>and</strong> City of Phoenix, <strong>and</strong> is a motivational/inspirational speaker nationally<br />

<strong>and</strong> internationally.<br />

Eric Pearce S.M.E., chemistry <strong>and</strong> biological review.<br />

Pete Greer S.M.E., retired biology instructor.<br />

Jack White, Environmental, Health, Safety Expert, City of Phoenix. Art Credits.<br />

WT303� 10/13/2011 TLC 5<br />

(866) 557-1746 Fax (928) 468-0675

WT303� 10/13/2011 TLC 6<br />

(866) 557-1746 Fax (928) 468-0675

<strong>Technical</strong> <strong>Learning</strong> <strong>College</strong>’s Scope <strong>and</strong> Function<br />

<strong>Technical</strong> <strong>Learning</strong> <strong>College</strong> (TLC) offers affordable continuing education for today’s<br />

working professionals who need to maintain licenses or certifications. TLC holds<br />

approximately eighty different governmental approvals for granting of continuing education<br />

credit.<br />

TLC’s delivery method of continuing education can include traditional types of classroom<br />

lectures <strong>and</strong> distance-based courses or independent study. Most TLC’s distance based or<br />

independent study courses are offered in a print based format <strong>and</strong> you are welcome to<br />

examine this material on your computer with no obligation. Our courses are designed to be<br />

flexible <strong>and</strong> for you do finish the material on your leisure. Students can also receive course<br />

materials through the mail. The CEU course or e-manual will contain all your lessons,<br />

activities <strong>and</strong> assignments. Most CEU courses allow students to submit lessons using email<br />

or fax; however some courses require students to submit lessons by postal mail. (See<br />

the course description for more information.) Students have direct contact with their<br />

instructor—primarily by e-mail. TLC’s CEU courses may use such technologies as the<br />

World Wide Web, e-mail, CD-ROMs, videotapes <strong>and</strong> hard copies. (See the course<br />

description.) Make sure you have access to the necessary equipment before enrolling, i.e.,<br />

printer, Microsoft Word <strong>and</strong>/or Adobe Acrobat Reader. Some courses may require<br />

proctored exams depending upon your state requirements.<br />

Flexible <strong>Learning</strong><br />

At TLC, there are no scheduled online sessions you need contend with, nor are you<br />

required to participate in learning teams or groups designed for the "typical" younger<br />

campus based student. You will work at your own pace, completing assignments in time<br />

frames that work best for you. TLC's method of flexible individualized instruction is<br />

designed to provide each student the guidance <strong>and</strong> support needed for successful course<br />

completion.<br />

We will beat any other training competitor’s price for the same CEU material or classroom<br />

training. Student satisfaction is guaranteed.<br />

Course Structure<br />

TLC's online courses combine the best of online delivery <strong>and</strong> traditional university<br />

textbooks. Online you will find the course syllabus, course content, assignments, <strong>and</strong><br />

online open book exams. This student friendly course design allows you the most flexibility<br />

in choosing when <strong>and</strong> where you will study.<br />

Classroom of One<br />

TLC Online offers you the best of both worlds. You learn on your own terms, on your own<br />

time, but you are never on your own. Once enrolled, you will be assigned a personal<br />

Student Service Representative who works with you on an individualized basis throughout<br />

your program of study. Course specific faculty members are assigned at the beginning of<br />

each course providing the academic support you need to successfully complete each<br />

course.<br />

WT303� 10/13/2011 TLC 7<br />

(866) 557-1746 Fax (928) 468-0675

Satisfaction Guaranteed<br />

Our Iron-Clad, Risk-Free Guarantee ensures you will be another satisfied TLC student.<br />

We have many years of experience, dealing with thous<strong>and</strong>s of students. We assure you, our<br />

customer satisfaction is second to none. This is one reason we have taught more than 20,000<br />

students.<br />

Our administrative staff is trained to provide the best customer service in town. Part of<br />

that training is knowing how to solve most problems on the spot with an exchange or<br />

refund.<br />

TLC Continuing Education Course Material Development<br />

<strong>Technical</strong> <strong>Learning</strong> <strong>College</strong>’s (TLC’s) continuing education course material development<br />

was based upon several factors; extensive academic research, advice from subject<br />

matter experts, data analysis, task analysis <strong>and</strong> training needs assessment process<br />

information gathered from other states.<br />

Rush Grading Service<br />

If you need this assignment graded <strong>and</strong> the results mailed to you within a 48-hour<br />

period, prepare to pay an additional rush service h<strong>and</strong>ling fee of $50.00. This fee<br />

may not cover postage costs. If you need this service, simply write RUSH on the top<br />

of your Registration Form. We will place you in the front of the grading <strong>and</strong><br />

processing line.<br />

For security purposes, please fax or e-mail a copy of your driver’s license <strong>and</strong> always<br />

call us to confirm we’ve received your assignment <strong>and</strong> to confirm your identity.<br />

Thank you…<br />

Please fax or e-mail the answer key to TLC<br />

Western Campus Fax (928) 272-0747 Back-up Fax (928) 468-0675.<br />

WT303� 10/13/2011 TLC 8<br />

(866) 557-1746 Fax (928) 468-0675

Water Treatment 303 CEU Training Course Description<br />

This distance learning CEU training course will examine various aspects of conventional water<br />

treatment methods, underst<strong>and</strong>ing pathogens, underst<strong>and</strong> the disinfection process, <strong>and</strong> review<br />

federal drinking water rules <strong>and</strong> regulations. This course will also cover water treatment pumps<br />

<strong>and</strong> motors. This course was designed to provide continuing education credit to water<br />

treatment operators.<br />

Water Distribution, Well Drillers, Pump Installers, Water Treatment Operators, Water Treatment<br />

Specialists <strong>and</strong> Customer Service Personnel are welcomed to take this course. The target<br />

audience for this course is the person interested in working in a water treatment or distribution<br />

facility <strong>and</strong>/or wishing to maintain CEUs for a certification license or to learn how to do the job<br />

safely <strong>and</strong> effectively <strong>and</strong>/or to meet education needs for promotion.<br />

Task Analysis <strong>and</strong> Training Needs Assessments have been conducted to determine or set<br />

Needs-To-Know for this CEU course. The following is a listing of some of those who have<br />

conducted extensive valid studies from which TLC has based this program upon: the<br />

Environmental Protection Agency (EPA), the Arizona Department of Environmental Quality<br />

(ADEQ), the Texas Commission of Environmental Quality (TCEQ) <strong>and</strong> the American Boards of<br />

Certification (ABC).<br />

Final Examination for Credit<br />

Opportunity to pass the final comprehensive examination is limited to three attempts per course<br />

enrollment.<br />

Course Procedures for Registration <strong>and</strong> Support<br />

All of TLC’s correspondence courses have complete registration <strong>and</strong> support service offered.<br />

Delivery of service will include, e-mail, web site, telephone, fax <strong>and</strong> mail support. TLC will<br />

attempt immediate <strong>and</strong> prompt service. When a student registers for a distance or<br />

correspondence course, he or she is assigned a start date <strong>and</strong> an end date. It is the student’s<br />

responsibility to note dates for assignments <strong>and</strong> keep up with the course work. If a student falls<br />

behind, he/she must contact TLC <strong>and</strong> request an end date extension in order to complete the<br />

course. It is the prerogative of TLC to decide whether to grant the request. All students will be<br />

tracked by a unique assigned number.<br />

<strong>Instructions</strong> for Written Assignments<br />

The Water Treatment 303 CEU training course uses a multiple-choice <strong>and</strong> fill-in-the-blank<br />

answer key. You can find the Microsoft Word version on the Assignment page. We would prefer<br />

the answers are typed <strong>and</strong> faxed or e-mailed to info@tlch2o.com. If you are unable to do so,<br />

please write inside the assignment booklet, make a copy for yourself <strong>and</strong> mail us the completed<br />

manual. Please feel free to call us if you need assistance.<br />

Other Student Information<br />

Feedback Mechanism (Examination procedures)<br />

Each student will receive a feedback form as part of their study packet. You will be able to find<br />

this form in the rear of the course or lesson. By completing this form, you can help us improve<br />

our course <strong>and</strong> serve your need better in the future.<br />

WT303� 10/13/2011 TLC 9<br />

(866) 557-1746 Fax (928) 468-0675

Security <strong>and</strong> Integrity<br />

All students are required to do their own work. All lesson sheets <strong>and</strong> final exams are not<br />

returned to the student to discourage sharing of answers. Any fraud or deceit will result in the<br />

student forfeiting all fees, <strong>and</strong> the appropriate agency will be notified.<br />

Grading Criteria<br />

TLC offers the student either pass/fail or a st<strong>and</strong>ard letter grading assignment if we are notified<br />

by the student. If we are not notified, you will only receive a certificate for passing the test.<br />

Recordkeeping <strong>and</strong> Reporting Practices<br />

TLC will keep all student records for a minimum of seven years. It is the student’s responsibility<br />

to give the completion certificate to the appropriate agencies. TLC will not release any records<br />

to any party, except to the student self.<br />

ADA Compliance<br />

TLC will make reasonable accommodations for persons with documented disabilities. Students<br />

should notify TLC <strong>and</strong> their instructors of any special needs. Course content may vary from this<br />

outline to meet the needs of this particular group.<br />

Note to Students<br />

Keep a copy of everything that you submit! If your work is lost, you can submit your copy for<br />

grading. If you do not receive your certificate of completion or other results within two to three<br />

weeks after submitting it, please contact your instructor.<br />

Educational Mission<br />

The educational mission of TLC is:<br />

To provide TLC students with comprehensive <strong>and</strong> ongoing training in the theory <strong>and</strong> skills<br />

needed for the pesticide application field,<br />

To provide TLC students with opportunities to underst<strong>and</strong> <strong>and</strong> apply the theory <strong>and</strong> skills<br />

needed for pesticide application certification,<br />

To provide opportunities for TLC students to learn <strong>and</strong> practice pesticide application skills with<br />

members of the community for the purpose of sharing diverse perspectives <strong>and</strong> experience,<br />

To provide a forum in which students can exchange experiences <strong>and</strong> ideas related to pesticide<br />

application education,<br />

To provide a forum for the collection <strong>and</strong> dissemination of current information related to<br />

pesticide application education, <strong>and</strong><br />

To maintain an environment that nurtures academic <strong>and</strong> personal growth.<br />

Mission Statement<br />

Our only product is educational service. Our goal is to provide you with the best education<br />

service possible. TLC attempts to make your learning experience an enjoyable educational<br />

opportunity.<br />

WT303� 10/13/2011 TLC 10<br />

(866) 557-1746 Fax (928) 468-0675

TABLE OF CONTENTS<br />

Water Treatment Terms 15<br />

Water Treatment 21<br />

Preliminary Treatment 23<br />

Rapid S<strong>and</strong> 31<br />

Backwash Rule 39<br />

Types of Filters 43<br />

Jar Testing 47<br />

Measuring Turbidity 49<br />

Potassium Permanganate 53<br />

Dissolved Oxygen 62<br />

Total Dissolved Solids 63<br />

Total Organic Carbon 65<br />

Surface Wash 71<br />

Pressure Filters 73<br />

Filtration Process 77<br />

Backwash Process 79<br />

Chemical Treatment 83<br />

Water Treatment Chemicals 87<br />

Solubility 89<br />

Coagulation 91<br />

Hard Water 97<br />

Membrane Filtration 105<br />

Reverse Osmosis 109<br />

GAC PAC 113<br />

Ultraviolet Radiation 117<br />

Corrosion Control 121<br />

Alkalinity 124<br />

Surface Wash 127<br />

Water Production 131<br />

Contaminated Wells 135<br />

Groundwater 138<br />

Well Surging 147<br />

Pumping Equipment 150<br />

Water Storage 157<br />

Underst<strong>and</strong>ing Water Quality 159<br />

Types of Algae 155<br />

Bacteriological Monitoring 167<br />

Heterotrophic Plate Count 173<br />

Total Coliforms 176<br />

Pathogens 177<br />

Viral Diseases 179<br />

Cryptosporidiosis 181<br />

General Contaminants 183<br />

Chain of Custody 187<br />

Sampling Plans 191<br />

pH Scale 195<br />

Disinfection Terminology 196<br />

Service Connections 375<br />

Chemical Monitoring 197<br />

Troubleshooting Sampling 201<br />

Microbes 203<br />

MCLs 213<br />

New EPA Rules 215<br />

Primary Water Regulations 219<br />

Secondary St<strong>and</strong>ards 225<br />

Chlorine 229<br />

Chemical Equations 235<br />

Chemistry of Chlorination 241<br />

DDBPs 245<br />

Chlorination Equipment 249<br />

Troubleshooting Hypochlorination 253<br />

Alternate Disinfectants 255<br />

Chlorine Exposure 263<br />

Fluoride 265<br />

Pump, Motors <strong>and</strong> Hydraulics 269<br />

Hydraulic Terms 271<br />

Pressure 276<br />

Atmospheric Pressure 279<br />

Pump Definitions 283<br />

Types of Pumps 287<br />

Pump Categories 289<br />

Underst<strong>and</strong>ing the Pump 291<br />

Submersible Pump 295<br />

Vertical Turbine 297<br />

Centrifugal Pump 303<br />

Pump Performance 310<br />

Motors, Couplings <strong>and</strong> Bearing 315<br />

Slip Ring 324<br />

Couplings 325<br />

Mechanical Seals 329<br />

Maintenance 331<br />

Troubleshooting Pumps 333<br />

Backflow 337<br />

Cross-Connection Terms 339<br />

Backpressure 343<br />

Backflow Responsibility 345<br />

Methods <strong>and</strong> Assemblies 347<br />

Water Distribution Section 353<br />

Distribution Design 355<br />

Distribution Valves 357<br />

Common Rotary Valves 359<br />

Needle Valves 363<br />

Butterfly 367<br />

Actuators <strong>and</strong> Control Devices 369<br />

Pressure Reducing Valve 373<br />

WT303� 10/13/2011 TLC 11<br />

(866) 557-1746 Fax (928) 468-0675

System Layouts 379<br />

Types of Pipes 383<br />

Troubleshooting Distribution 389<br />

Glossary 391<br />

Microorganism Appendix 431<br />

Protozoa 433<br />

Protozoan Diseases 443<br />

Giardia Lamblia 445<br />

Entamoeba Histolytica 448<br />

Bacteria Section 457<br />

Salmonella 463<br />

Escherichia Coli 465<br />

Math Conversions 485<br />

References 501<br />

WT303� 10/13/2011 TLC 12<br />

(866) 557-1746 Fax (928) 468-0675

Common Water Treatment Acronyms<br />

AA Activated alumina<br />

AC Activated carbon<br />

ASR Annual Status Report<br />

As(III) Trivalent arsenic, common inorganic form in water is arsenite, H3AsO3<br />

As(V) Pentavalent arsenic, common inorganic form in water is arsenate, H2AsO4<br />

BDAT best demonstrated available technology<br />

BTEX Benzene, toluene, ethylbenzene, <strong>and</strong> xylene<br />

CCA Chromated copper arsenate<br />

CERCLA Comprehensive Environmental Response, Compensation, <strong>and</strong> Liability Act<br />

CERCLIS 3 CERCLA Information System<br />

CLU-IN EPA’s CLeanUp INformation system<br />

CWS Community Water System<br />

cy Cubic yard<br />

DDT Dichloro-diphenyl-trichloroethane<br />

DI De-ionized<br />

DOC Dissolved organic carbon<br />

DoD Department of Defense<br />

DOE Department of Energy<br />

EDTA Ethylenediaminetetraacetic acid<br />

EPA U.S. Environmental Protection Agency<br />

EPT Extraction Procedure Toxicity Test<br />

FRTR Federal Remediation Technologies Roundtable<br />

ft feet<br />

GJO DOE’s Gr<strong>and</strong> Junction Office<br />

gpd gallons per day<br />

gpm gallons per minute<br />

HTMR High temperature metals recovery<br />

MCL Maximum Contaminant Level (enforceable drinking water st<strong>and</strong>ard)<br />

MF Microfiltration<br />

MHO Metallurgie-Hoboken-Overpelt<br />

mgd million gallons per day<br />

mg/kg milligrams per kilogram<br />

mg/L milligrams per Liter<br />

NF Nanofiltration<br />

NPL National Priorities List<br />

OCLC Online Computer Library Center<br />

ORD EPA Office of Research <strong>and</strong><br />

Development<br />

OU Operable Unit<br />

PAH Polycyclic aromatic hydrocarbons<br />

PCB Polychlorinated biphenyls<br />

POTW Publicly owned treatment works<br />

PRB Permeable reactive barrier<br />

RCRA Resource Conservation <strong>and</strong> Recovery Act<br />

Redox Reduction/oxidation<br />

RO Reverse osmosis<br />

ROD Record of Decision<br />

SDWA Safe Drinking Water Act<br />

WT303� 10/13/2011 TLC 13<br />

(866) 557-1746 Fax (928) 468-0675

SMZ surfactant modified zeolite<br />

SNAP Superfund NPL Assessment Program<br />

S/S Solidification/Stabilization<br />

SVOC Semi-volatile organic compounds<br />

TCLP Toxicity Characteristic Leaching<br />

Procedure<br />

TNT 2,3,6-trinitrotoluene<br />

TWA Total Waste Analysis<br />

UF Ultrafiltration<br />

VOC Volatile organic compounds<br />

WET Waste Extraction Test<br />

ZVI Zero valent iron<br />

Operator Control Panel<br />

WT303� 10/13/2011 TLC 14<br />

(866) 557-1746 Fax (928) 468-0675

Water Treatment Terms<br />

Community Water System (CWS). A public water system that serves at least 15 service<br />

connections used by year-round residents of the area served by the system or regularly serves<br />

at least 25 year-round residents.<br />

Class V Underground Injection Control (UIC). Rule A rule under development covering<br />

wells not included in Class I, II, III or IV in which nonhazardous fluids are injected into or above<br />

underground sources of drinking water.<br />

Contamination Source Inventory. The process of identifying <strong>and</strong> inventorying contaminant<br />

sources within delineated source water protection areas through recording existing data,<br />

describing sources within the source water protection area, targeting likely sources for further<br />

investigation, collecting <strong>and</strong> interpreting new information on existing or potential sources<br />

through surveys, <strong>and</strong> verifying accuracy <strong>and</strong> reliability of the information gathered.<br />

Cryptosporidium. A protozoan associated with the disease cryptosporidiosis in humans. The<br />

disease can be transmitted through ingestion of drinking water, person-to-person contact, or<br />

other exposure routes. Cryptosporidiosis may cause acute diarrhea, abdominal pain, vomiting,<br />

<strong>and</strong> fever that last 1-2 weeks in healthy adults, but may be chronic or fatal in immunocompromised<br />

people.<br />

Drinking Water State Revolving Fund (DWSRF). Under section 1452 of the SDWA, the EPA<br />

awards capitalization grants to states to develop drinking water revolving loan funds to help<br />

finance drinking water system infrastructure improvements, source water protection, to<br />

enhance operations <strong>and</strong> management of drinking water systems, <strong>and</strong> other activities to<br />

encourage public water system compliance <strong>and</strong> protection of public health.<br />

Exposure. Contact between a person <strong>and</strong> a chemical. Exposures are calculated as the<br />

amount of chemical available for absorption by a person.<br />

Giardia lamblia. A protozoan, which can survive in water for 1 to 3 months, associated with<br />

the disease giardiasis. Ingestion of this protozoan in contaminated drinking water, exposure<br />

from person-to-person contact, <strong>and</strong> other exposure routes may cause giardiasis. The<br />

symptoms of this gastrointestinal disease may persist for weeks or months <strong>and</strong> include<br />

diarrhea, fatigue, <strong>and</strong> cramps.<br />

Ground Water Disinfection Rule (GWDR). Under section 107 of the SDWA Amendments of<br />

1996, the statute reads, ". . . the Administrator shall also promulgate national primary drinking<br />

water regulations requiring disinfection as a treatment technique for all public water systems,<br />

including surface water systems, <strong>and</strong> as necessary, ground water systems."<br />

Maximum Contaminant Level (MCL). In the SDWA, an MCL is defined as "the maximum<br />

permissible level of a contaminant in water which is delivered to any user of a public<br />

water system." MCLs are enforceable st<strong>and</strong>ards.<br />

Maximum Contaminant Level Goal (MCLG). The maximum level of a contaminant in<br />

drinking water at which no known or anticipated adverse effect on the health effect of persons<br />

would occr, <strong>and</strong> which allows for an adequate margin of safety. MCLGs are non-enforceable<br />

public health goals.<br />

WT303� 10/13/2011 TLC 15<br />

(866) 557-1746 Fax (928) 468-0675

Nephelolometric Turbidity Units (NTU). A unit of measure used to describe the turbidity of<br />

water. Turbidity is the cloudiness in water.<br />

Nitrates. Inorganic compounds that can enter water supplies from fertilizer runoff <strong>and</strong> sanitary<br />

wastewater discharges. Nitrates in drinking water are associated with methemoglobanemia, or<br />

blue baby syndrome, which results from interferences in the blood’s ability to carry oxygen.<br />

Non-Community Water System (NCWS). A public water system that is not a community<br />

water system. There are two types of NCWSs: transient <strong>and</strong> non-transient.<br />

Organics. Chemical molecules contain carbon <strong>and</strong> other elements such as hydrogen. Organic<br />

contaminants of concern to drinking water include chlorohydrocarbons, pesticides, <strong>and</strong> others.<br />

Phase I Contaminants. The Phase I Rule became effective on January 9, 1989. This rule,<br />

also called the Volatile Organic Chemical Rule, or VOC Rule, set water quality st<strong>and</strong>ards for 8<br />

VOCs <strong>and</strong> required all community <strong>and</strong> Non-Transient, Non-Community water systems to<br />

monitor for, <strong>and</strong> if necessary, treat their supplies for these chemicals. The 8 VOCs regulated<br />

under this rule are: Benzene, Carbon Tetrachloride, para-dichlorobenzene, trichloroethylene,<br />

vinyl chloride, 1,1,2-trichlorethane, 1,1-dichloroethylene, <strong>and</strong> 1,2-dichlorothane.<br />

Per capita. Per person; generally used in expressions of water use, gallons per capita per day<br />

(gpcd).<br />

Point-of-Use Water Treatment. Refers to devices used in the home or office on a specific tap<br />

to provide additional drinking water treatment.<br />

Point-of-Entry Water Treatment. Refers to devices used in the home where water pipes<br />

enter to provide additional treatment of drinking water used throughout the home.<br />

Primacy State State that has the responsibility for ensuring a law is implemented, <strong>and</strong> has<br />

the authority to enforce the law <strong>and</strong> related regulations. State has adopted rules at least as<br />

stringent as federal regulations <strong>and</strong> has been granted primary enforcement responsibility.<br />

Radionuclides. Elements that undergo a process of natural decay. As radionuclides decay,<br />

they emit radiation in the form of alpha or beta particles <strong>and</strong> gamma photons. Radiation can<br />

cause adverse health effects, such as cancer, so limits are placed on radionuclide<br />

concentrations in drinking water.<br />

Risk. The potential for harm to people exposed to chemicals. In order for there to be risk,<br />

there must be hazard <strong>and</strong> there must be exposure.<br />

SDWA - The Safe Drinking Water Act. The Safe Drinking Water Act was first passed in 1974<br />

<strong>and</strong> established the basic requirements under which the nation’s public water supplies were<br />

regulated. The US Environmental Protection Agency (EPA) is responsible for setting the<br />

national drinking water regulations, while individual states are responsible for ensuring that<br />

public water systems under their jurisdiction are complying with the regulations. The SDWA<br />

was amended in 1986 <strong>and</strong> again in 1996.<br />

Significant Potential Source of Contamination. A facility or activity that stores, uses, or<br />

produces chemicals or elements, <strong>and</strong> that has the potential to release contaminants identified<br />

in a state program (contaminants with MCLs plus any others a state considers a health threat)<br />

WT303� 10/13/2011 TLC 16<br />

(866) 557-1746 Fax (928) 468-0675

within a source water protection area in an amount which could contribute significantly to the<br />

concentration of the contaminants in the source waters of the public water supply.<br />

Sole Source Aquifer (SSA) Designation. The surface area above a sole source aquifer <strong>and</strong><br />

its recharge area.<br />

Source Water Protection Area (SWPA). The area delineated by the state for a PWS or<br />

including numerous PWSs, whether the source is ground water or surface water or both, as<br />

part of the state SWAP approved by the EPA under section 1453 of the SDWA.<br />

Sub-watershed. A topographic boundary that is the perimeter of the catchment area of a<br />

tributary of a stream.<br />

State Source Water Petition Program. A state program implemented in accordance with the<br />

statutory language at section 1454 of the SDWA to establish local voluntary incentive-based<br />

partnerships for SWP <strong>and</strong> remediation.<br />

State Management Plan (SMP) Program. A state management plan under FIFRA required<br />

by the EPA to allow states (e.g. states, tribes <strong>and</strong> U.S. territories) the flexibility to design <strong>and</strong><br />

implement approaches to manage the use of certain pesticides to protect ground water.<br />

Surface Water Treatment Rule (SWTR). The rule specifies maximum contaminant level<br />

goals for Giardia lamblia, viruses <strong>and</strong> Legionella, <strong>and</strong> promulgated filtration <strong>and</strong> disinfection<br />

requirements for public water systems using surface water sources, or by ground water<br />

sources under the direct influence of surface water. The regulations also specify water quality,<br />

treatment, <strong>and</strong> watershed protection criteria under which filtration may be avoided.<br />

Susceptibility Analysis. An analysis to determine, with a clear underst<strong>and</strong>ing of where the<br />

significant potential sources of contamination are located, the susceptibility of the public water<br />

systems in the source water protection area to contamination from these sources. This<br />

analysis will assist the state in determining which potential sources of contamination are<br />

"significant."<br />

To the Extent Practical. States must inventory sources of contamination to the extent they<br />

have the technology <strong>and</strong> resources to complete an inventory for a Source Water Protection<br />

Area delineated as described in the guidance. All information sources may be used,<br />

particularly previous Federal <strong>and</strong> state inventories of sources.<br />

Transient/Non-Transient, Non-Community Water Systems (T/NT, NCWS). Water systems<br />

that are non-community systems: transient systems serve 25 non-resident persons per day for<br />

6 months or less per year. Transient non-community systems typically are restaurants, hotels,<br />

large stores, etc. Non-transient systems regularly serve at least 25 of the same non-resident<br />

persons per day for more than 6 months per year. These systems typically are schools,<br />

offices, churches, factories, etc.<br />

Treatment Technique. A specific treatment method required by the EPA to be used to control<br />

the level of a contaminant in drinking water. In specific cases where the EPA has determined it<br />

is not technically or economically feasible to establish an MCL, the EPA can instead specify a<br />

treatment technique. A treatment technique is an enforceable procedure or level of technical<br />

performance which public water systems must follow to ensure control of a contaminant.<br />

WT303� 10/13/2011 TLC 17<br />

(866) 557-1746 Fax (928) 468-0675

Total Coliform. Bacteria that are used as indicators of fecal contaminants in drinking water.<br />

Toxicity. The property of a chemical to harm people who come into contact with it.<br />

Underground Injection Control (UIC) Program. The program is designed to prevent<br />

underground injection which endangers drinking water sources. The program applies to<br />

injection well owners <strong>and</strong> operators on Federal facilities, Native American l<strong>and</strong>s, <strong>and</strong> on all<br />

U.S. l<strong>and</strong> <strong>and</strong> territories.<br />

Watershed. A topographic boundary area that is the perimeter of the catchment area of a<br />

stream.<br />

Watershed Approach. A watershed approach is a coordinating framework for environmental<br />

management that focuses public <strong>and</strong> private sector efforts to address the highest priority<br />

problems within hydrologically-defined geographic areas, taking into consideration both ground<br />

<strong>and</strong> surface water flow.<br />

Watershed Area. A topographic area that is within a line drawn connecting the highest points<br />

uphill of a drinking water intake, from which overl<strong>and</strong> flow drains to the intake.<br />

Wellhead Protection Area (WHPA). The surface <strong>and</strong> subsurface area surrounding a well or<br />

well field, supplying a PWS, through which contaminants are reasonably likely to move toward<br />

<strong>and</strong> reach such water well or well field.<br />

More SDWA Information<br />

Any federal agency having jurisdiction over federally owned <strong>and</strong> maintained public water<br />

systems must comply with all federal, state, <strong>and</strong> local drinking water requirements as well as<br />

any underground injection control programs (Section 1447). The Act provides for waivers in<br />

the interest of national security.<br />

Procedures for judicial review are outlined (Section 1448), <strong>and</strong> provision for citizens' civil<br />

actions is made (Section 1449). Citizen suits may be brought against any person or agency<br />

allegedly in violation of provisions of the Act, or against the Administrator for alleged failure to<br />

perform any action or duty which is not discretionary.<br />

EPA may use the new estrogenic substances screening program created in the Food Quality<br />

Protection Act of 1996 (P .L. 104-170) to provide for testing of substances that may be found<br />

in drinking water if the Administrator determines that a substantial population may be exposed<br />

to such substances (Section 1457).<br />

EPA is directed to conduct drinking water studies involving subpopulations at greater risk <strong>and</strong><br />

biological mechanisms, <strong>and</strong> studies to support several rules including those addressing<br />

D/DBPs <strong>and</strong> Cryptosporidium. The Centers for Disease Control <strong>and</strong> Prevention <strong>and</strong> EPA<br />

must conduct pilot waterborne disease occurrence studies by August 1998. (Section 1458).<br />

The Act includes a provision amending the Federal Food, Drug, <strong>and</strong> Cosmetic Act, generally<br />

requiring the Secretary of Health <strong>and</strong> Human Services to issue bottled drinking water<br />

st<strong>and</strong>ards for contaminants regulated under the Safe Drinking Water Act.<br />

WT303� 10/13/2011 TLC 18<br />

(866) 557-1746 Fax (928) 468-0675

Other provisions of P.L. 104-182 authorize water <strong>and</strong> wastewater grants for colonias <strong>and</strong><br />

Alaska rural <strong>and</strong> native villages, <strong>and</strong> authorize the transfer of the Washington (D.C.) Aqueduct<br />

to a regional authority.<br />

The 1996 Amendments also authorize a $50 million per year grant program for additional<br />

infrastructure <strong>and</strong> watershed protection projects; the conference report lists, <strong>and</strong> directs EPA<br />

to give priority consideration to, 24 such projects.<br />

IDEXX’s SimPlate for HPC method is used for the quantification of heterotrophic plate<br />

count (HPC) in water. It is based on the Multiple Enzyme Technology which detects<br />

viable bacteria in water by testing for the presence of key enzymes known to be<br />

present in these little organisms. This technique uses enzyme substrates that produce<br />

a blue fluorescence when metabolized by waterborne bacteria. The sample <strong>and</strong><br />

media are added to a SimPlate Plate, incubated <strong>and</strong> then examined for fluorescing<br />

wells. The number of wells corresponds to a Most Probable Number (MPN) of total<br />

bacteria in the original sample. The MPN values generated by the SimPlate for HPC<br />

method correlate with the Pour Plate method using the Total Plate Count Agar,<br />

incubated at 35 o C for 48 hours as described in St<strong>and</strong>ard Methods for the Examination<br />

of Water <strong>and</strong> Wastewater, 19 th Edition.<br />

We will be more into detail in the Water Monitoring Section.<br />

WT303� 10/13/2011 TLC 19<br />

(866) 557-1746 Fax (928) 468-0675

Sampling Plan<br />

A written sampling plan must be developed by the water system. These plans will be reviewed<br />

by the Health Department or State Drinking Water agency during routine field visits for sanitary<br />

surveys or technical assistance visits. This plan should include:<br />

1. The location of routine sampling sites on a system distribution map. You will need to locate<br />

more routine sampling sites than the number of samples required per month or quarter. A<br />

minimum of three sites is advised <strong>and</strong> the sites should be rotated on a regular basis.<br />

2. Map the location of repeat sampling sites for the routine sampling sites. Remember that<br />

repeat samples must be collected within five (5) connections upstream <strong>and</strong> downstream from<br />

the routine sample sites.<br />

3. Establish a sampling frequency of the routine sites.<br />

4. Sampling technique, establish a minimum flushing time <strong>and</strong> requirements for free chlorine<br />

residuals at the sites (if you chlorinate continuously).<br />

The sampling sites should be representative of the distribution network <strong>and</strong> pressure zones. If<br />

someone else, e.g., the lab, collects samples for you, you should provide them with a copy of<br />

your sampling plan <strong>and</strong> make sure they have access to all sample sites.<br />

Grabbing a sample from a stream.<br />

WT303� 10/13/2011 TLC 20<br />

(866) 557-1746 Fax (928) 468-0675

Water Treatment Section<br />

For thous<strong>and</strong>s of years, people have treated water intended for drinking to remove particles of<br />

solid matter, reduce health risks, <strong>and</strong> improve aesthetic qualities such as appearance, odor,<br />

color, <strong>and</strong> taste. As early as 2000 B.C., medical lore of India advised, “Impure water should<br />

be purified by being boiled over a fire, or being heated in the sun or by dipping a heated<br />

iron into it, or it may be purified by filtration through s<strong>and</strong> <strong>and</strong> coarse gravel <strong>and</strong> then<br />

allowed to cool.”<br />

The treatment needs of a water system are likely to differ depending on whether the system<br />

uses a groundwater or surface water source. Common surface water contaminants include<br />

turbidity, microbiological contaminants (Giardia, viruses <strong>and</strong> bacteria) <strong>and</strong> low levels of a<br />

large number of organic chemicals. Groundwater contaminants include naturally occurring<br />

inorganic chemicals (such as arsenic, fluoride, radium, radon <strong>and</strong> nitrate) <strong>and</strong> a number of<br />

volatile organic chemicals (VOCs) that have recently been detected in localized areas.<br />

When selecting among the different treatment options, the water supplier must consider a<br />

number of factors. These include regulatory requirements, characteristics of the raw water,<br />

configuration of the existing system, cost, operating requirements <strong>and</strong> future needs of the<br />

service area.<br />

Here is a surface water conventional treatment facility next to a river.<br />

WT303� 10/13/2011 TLC 21<br />

(866) 557-1746 Fax (928) 468-0675

Top Photograph - Final Rectangle Sedimentation Basin<br />

Bottom - Clarifier<br />

WT303� 10/13/2011 TLC 22<br />

(866) 557-1746 Fax (928) 468-0675

Preliminary Treatment<br />

Most lakes <strong>and</strong> reservoirs are not free of logs, tree limbs, sticks, gravel, s<strong>and</strong> <strong>and</strong> rocks,<br />

weeds, leaves, <strong>and</strong> trash. If not removed, these will cause problems to the treatment plant’s<br />

pumps <strong>and</strong> equipment. The best way to protect the plant is screening.<br />

Bar screens are made of straight steel bars at the intake of the plant. The spacing of the<br />

horizontal bars will rank the size. Wire mesh screens are woven stainless steel material <strong>and</strong><br />

the opening of the fabric is narrow. Both require manual cleaning.<br />

Mechanical bar screens vary in size <strong>and</strong> use some type of raking mechanism that travels<br />

horizontally down the bars to scrap the debris off. The type of screening used depends on the<br />

raw water <strong>and</strong> the size of the intake.<br />

Mechanical bar screen, above photograph.<br />

Non-automated bar screen, below.<br />

WT303� 10/13/2011 TLC 23<br />

(866) 557-1746 Fax (928) 468-0675

Pre-Sedimentation<br />

Once the water passes the bar screens, s<strong>and</strong> <strong>and</strong> grit are still present. This will damage plant<br />

equipment <strong>and</strong> pipes, so it must be removed. This is generally done with either rectangular- or<br />

round-shaped clarifers. Sedimentation basins are also used after the flocculation process.<br />

Let’s first look at the components of a rectangular clarifier. Most are designed with scrapers on<br />

the bottom to move the settled sludge to one or more hoppers at the influent end of the tank. It<br />

could have a screw conveyor or traveling bridge used to collect the sludge. The most common<br />

is a chain <strong>and</strong> flight collector. Most designs will have baffles to prevent short circuiting <strong>and</strong><br />

scum from entering the effluent.<br />

WT303� 10/13/2011 TLC 24<br />

(866) 557-1746 Fax (928) 468-0675

Flights <strong>and</strong> Chains<br />

The most important thing to consider is the sludge <strong>and</strong> scum collection mechanism known as<br />

the “flights <strong>and</strong> chains”. They move the settled sludge to the hopper in the clarifier for return<br />

<strong>and</strong> they also remove the scum from the surface of the clarifier. The flights are usually wood or<br />

nonmetallic flights mounted on parallel chains. The motor shaft is connected through a gear<br />

reducer to a shaft which turns the drive chain. The drive chain turns the drive sprockets <strong>and</strong><br />

the head shafts. The shafts can be located overhead or below.<br />

Some clarifiers may not have scum removal equipment, so the configuration of the shaft may<br />

vary. As the flights travel across the bottom of the clarifier, wearing shoes are used to protect<br />

the flights. The shoes are usually metal <strong>and</strong> travel across a metal track.<br />

To prevent damage due to overloads, a shear pin is used. The shear pin holds the gear solidly<br />

on the shaft so that no slippage occurs. Remember, the gear moves the drive chain. If a heavy<br />

load is put on the sludge collector system then the shear pin should break. This means that<br />

the gear would simply slide around the shaft <strong>and</strong> movement of the drive chain would stop.<br />

Rectangular basin flights <strong>and</strong> chains.<br />

WT303� 10/13/2011 TLC 25<br />

(866) 557-1746 Fax (928) 468-0675

Circular Clarifiers<br />

In some circular or square tanks, rotating scrapers are used. The diagram below shows a<br />

typical circular clarifier. The most common type has a center pier or column. The major<br />

mechanic parts of the clarifier are the drive unit; the sludge collector mechanism, <strong>and</strong> the<br />

scum removal system.<br />

Circular clarifier <strong>and</strong> collector mechanism.<br />

WT303� 10/13/2011 TLC 26<br />

(866) 557-1746 Fax (928) 468-0675

Pre-Treatment<br />

Once the water passes the bar screens, s<strong>and</strong> <strong>and</strong> grit are still present. This will damage plant<br />

equipment <strong>and</strong> pipes, so it must be removed. This is generally done with either rectangular or<br />

round shaped clarifiers. Sedimentation basins are also used after the flocculation process.<br />

Clarifiers<br />

Let’s first look at the components of a rectangular clarifier. Most are designed with scrapers on<br />

the bottom to move the settled sludge to one or more hoppers at the influent end of the tank. It<br />

could have a screw conveyor or traveling bridge used to collect the sludge. The most common<br />

is a chain <strong>and</strong> flight collector. Most designs will have baffles to prevent short-circuiting <strong>and</strong><br />

scum from entering the effluent.<br />

WT303� 10/13/2011 TLC 27<br />

(866) 557-1746 Fax (928) 468-0675

Direct Filtration Plant vs. Conventional Plant<br />

The only difference is that the sedimentation process or step is omitted from the Direct<br />

Filtration plant.<br />

Tours of your facility are a wonderful public image tool. I know that many facilities are<br />

worried about the public <strong>and</strong> what could possibly happen, but if you can think positive,<br />

you may find more support <strong>and</strong> funding for your future projects.<br />

WT303� 10/13/2011 TLC 28<br />

(866) 557-1746 Fax (928) 468-0675

Conventional Treatment Overview & Direct Filtration<br />

Improving the clarity of surface water has always presented a challenge because source<br />

quality varies. Traditional treatments rely on expensive, construction-intensive processes with<br />

lengthy times.<br />

Suspended particles carry an electrical charge which causes them to repel one another. The<br />

conventional process uses alum (aluminum sulfate) <strong>and</strong> cationic polymer to neutralize the<br />

charge. That allows suspended particles to clump together to form more easily filtered<br />

particles.<br />

Alum combines with alkalinity in the raw water to form a white precipitate that neutralizes<br />

suspended particles' electrical charge <strong>and</strong> forms a base for coagulating those particles.<br />

Conventional technology uses a 30 to 50 mg/L alum dosage to form a large floc that requires<br />

extensive retention time to permit settling. Traditional filter systems use graded silica s<strong>and</strong><br />

filter media. Since the s<strong>and</strong> grains all have about the same density, larger grains lay toward<br />

the bottom of the filter bed <strong>and</strong> finer grains lay at the top of the filter bed. As a result, filtration<br />

occurs only within the first few inches of the finer grains at the top of the bed.<br />

A depth filter has four layers of filtration media, each of different size <strong>and</strong> density. Light, coarse<br />

material lies at the top of the filter bed. The media become progressively finer <strong>and</strong> denser in<br />

the lower layers. Larger suspended particles are removed by the upper layers while smaller<br />

particles are removed in the lower layers. Particles are trapped throughout the bed, not in just<br />

the top few inches. That allows a depth filter to run substantially longer <strong>and</strong> use less backwash<br />

water than a traditional s<strong>and</strong> filter.<br />

As suspended particles accumulate in a filter bed, the pressure drop through the filter<br />

increases. When the pressure difference between filter inlet <strong>and</strong> outlet increases by 5 - 10 psi<br />

(34 to 68 kPa) from the beginning of the cycle, the filter should be reconditioned. Operating<br />

beyond this pressure drop increases the chance of fouling - called "mud-balling" - within the<br />

filter.<br />

The reconditioning cycle consists of an up-flow backwash followed by a down-flow rinse.<br />

Backwash is an up-flow operation, at about 14 gpm per square foot (34m/hr) of filter bed area<br />

that lasts about 10 minutes. Turbidity washes out of the filter bed as the filter media particles<br />

scour one another. The down-flow rinse settles the bed before the filter returns to service. Fast<br />

rinse lasts about 5 to 10 minutes.<br />

WT303� 10/13/2011 TLC 29<br />

(866) 557-1746 Fax (928) 468-0675

Chemical pretreatment is often used to enhance filter performance, particularly when turbidity<br />

includes fine colloidal particles. Suspended particles are usually electrically charged. Feeding<br />

chemicals such as alum (aluminum sulfate), ferric chloride, or a cationic polymer neutralizes<br />

the charge, allowing the particles to cling to one another <strong>and</strong> to the filter media.<br />

Chemical pretreatment may increase filtered water clarity, measured in NTU, by 90%<br />

compared with filtration alone. If an operator is present to make adjustments for variations in<br />

the raw water, filtered water clarity improvements in the range of 93 to 95% are achievable.<br />

Example of a small water treatment package plant coagulation, flocculation <strong>and</strong><br />

filtration all within a 20 foot area.<br />

Package Plants<br />

Representing a slight modification of conventional filtration technology, package plants are<br />

usually built in a factory, mounted on skids, <strong>and</strong> transported virtually assembled to the<br />

operation site.<br />

These are appropriate for small community systems where full water treatment is desired, but<br />

without the construction costs <strong>and</strong> space requirements associated with separately constructed<br />

sedimentation basins, filter beds, clear wells, etc.<br />

In addition to the conventional filtration processes, package plants are found as two types:<br />

tube-type clarifiers <strong>and</strong> adsorption clarifiers.<br />

WT303� 10/13/2011 TLC 30<br />

(866) 557-1746 Fax (928) 468-0675

Rapid S<strong>and</strong> Filtration<br />

Also known as rapid-s<strong>and</strong> filtration, this is the most prevalent form of water treatment<br />

technology in use today. This filtration process employs a combination of physical <strong>and</strong><br />

chemical processes in order to achieve maximum effectiveness, as follows:<br />

Coagulation<br />

At the Water Treatment Plant, aluminum sulfate, commonly called alum, is added to the water<br />

in the "flash mix" to cause microscopic impurities in the water to clump together. The alum<br />

<strong>and</strong> the water are mixed rapidly by the flash mixer. The resulting larger particles will be<br />

removed by filtration.<br />

Coagulation is the process of joining together particles in water to help remove organic matter.<br />

When solid matter is too small to be removed by a depth filter, the fine particles must be<br />

coagulated, or "stuck together" to form larger particles which can be filtered. This is achieved<br />

through the use of coagulant chemicals.<br />

Coagulant chemicals are required since colloidal particles by themselves have the tendency to<br />

stay suspended in water <strong>and</strong> not settle out. This is primarily due to a negative charge on the<br />

surface of the particles. All matter has a residual surface charge to a certain degree. But since<br />

colloidal particles are so small, their charge per volume is significant. Therefore, the like<br />

charges on the particles repel each other, <strong>and</strong> they stay suspended in water.<br />

Coagulant chemicals such as "alum" (aluminum Sulfate) work by neutralizing the negative<br />

charge, which allows the particles to come together. Other coagulants are called "cationic<br />

polymers", which can be thought of as positively charged strings that attract the particles to<br />

them, <strong>and</strong> in the process, form a larger particle. Also, new chemicals have been developed<br />

which combine the properties of alum-type coagulants <strong>and</strong> cationic polymers. Which chemical<br />

is used depends on the application, <strong>and</strong> will usually be chosen by the engineer designing the<br />

water treatment system.<br />

Aluminum Sulfate is the most widely used coagulant in water treatment. Coagulation is<br />

necessary to meet the current regulations for almost all potable water plants using surface<br />

water. Aluminum Sulfate is also excellent for removing nutrients such as phosphorous in<br />

wastewater treatment. Liquid Aluminum Sulfate is a 48.86% solution.<br />

Large microorganisms, including algae <strong>and</strong> amoebic cysts, are readily removed by coagulation<br />

<strong>and</strong> filtration. Bacterial removals of 99% are also achievable. More than 98% of poliovirus type<br />

1 was removed by conventional coagulation <strong>and</strong> filtration. Several recent studies have shown<br />

that bacterial <strong>and</strong> viral agents are attached to organic <strong>and</strong> inorganic particulates. Hence,<br />

removal of these particulates by conventional coagulation <strong>and</strong> filtration is a major component<br />

of effective treatment for the removal of pathogens.<br />

Flocculation<br />

The process of bringing together destabilized or coagulated particles to form larger masses<br />

which can be settled <strong>and</strong>/or filtered out of the water being treated. In this process, which<br />

follows the rapid mixing, the chemically treated water is sent into a basin where the suspended<br />

particles can collide, agglomerate (stick together), <strong>and</strong> form heavier particles called “floc”.<br />

Gentle agitation of the water <strong>and</strong> appropriate detention times (the length of time water remains<br />

in the basin) help facilitate this process.<br />

WT303� 10/13/2011 TLC 31<br />

(866) 557-1746 Fax (928) 468-0675

The water is slowly mixed in contact chambers allowing the coagulated particles, now called<br />

"floc," to become larger <strong>and</strong> stronger. As these floc particles mix in the water, bacteria <strong>and</strong><br />

other microorganisms are caught in the floc structure.<br />

Pre-Sedimentation<br />

Depending on the quality of the source water, some plants have pre-sedimentation.<br />

A. To allow larger particles time to settle in a reservoir or lake (s<strong>and</strong>, heavy silt) reducing solid<br />

removal loads.<br />

B. Provides an equalization basin which evens out fluctuations.<br />

Sedimentation Basin Zones<br />

A. Inlet Zone<br />

B. Settling Zone<br />

C. Sludge Zone<br />

D. Outlet Zone<br />

Shapes for a Sedimentation Basin<br />

A. Rectangular Basins<br />

B. Circular Basins<br />

C. Square Basins<br />

D. Double deck Basins<br />

Sedimentation<br />

The process of suspended solid particles settling out (going to the bottom of the vessel) in<br />

water.<br />

Following flocculation, a sedimentation step may be used. During sedimentation, the velocity<br />

of the water is decreased so that the suspended material, including flocculated particles, can<br />

settle out by gravity. Once settled, the particles combine to form a sludge that is later removed<br />

from the bottom of the basin.<br />

Filtration<br />

A water treatment step used to remove turbidity, dissolved organics,<br />

odor, taste <strong>and</strong> color. The water flows by gravity through large filters<br />

of anthracite coal, silica s<strong>and</strong>, garnet <strong>and</strong> gravel. The floc particles<br />

are removed in these filters. The rate of filtration can be adjusted to<br />

meet water consumption needs. Filters for suspended particle<br />

removal can also be made of graded s<strong>and</strong>, granular synthetic<br />

material, screens of various materials, <strong>and</strong> fabrics.<br />

The most widely used are rapid-s<strong>and</strong> filters in tanks. In these units,<br />

gravity holds the material in place <strong>and</strong> the flow is downward. The<br />

filter is periodically cleaned by a reversal of flow <strong>and</strong> the discharge<br />

of back-flushed water into a drain.<br />

Cartridge filters made of fabric, paper, or plastic material are also<br />

common <strong>and</strong> are often much smaller <strong>and</strong> cheaper, as well as<br />

disposable. Filters are available in several ratings, depending on the<br />

size of particles to be removed. Activated carbon filters, described<br />

earlier, will also remove turbidity, but would not be recommended for<br />

that purpose only.<br />

WT303� 10/13/2011 TLC 32<br />

(866) 557-1746 Fax (928) 468-0675

With most of the larger particles settled out, the water now goes to the filtration process. At a<br />

rate of between 2 <strong>and</strong> 10 gpm per square foot, the water is filtered through an approximate 36"<br />

depth of graded s<strong>and</strong>. Anthracite coal or activated carbon may also be included in the s<strong>and</strong> to<br />

improve the filtration process, especially for the removal of organic contaminants <strong>and</strong> taste<br />

<strong>and</strong> odor problems. The filtration process removes the following types of particles:<br />

� Silts <strong>and</strong> clay<br />

� Colloids<br />

� Biological forms<br />

� Floc<br />

Four Desirable Characteristics of Filter Media<br />

� Good hydraulic characteristics (permeable)<br />

� Does not react with substances in the water (inert <strong>and</strong> easy to clean)<br />

� Hard <strong>and</strong> durable<br />

� Free of impurities <strong>and</strong> insoluble in water<br />

Evaluation of overall filtration process performance should be conducted on a routine basis, at<br />

least once per day. Poor chemical treatment can often result in either early turbidity<br />

breakthrough or rapid head loss buildup. The more uniform the media, the slower head loss<br />

buildup. All water treatment plants that use surface water are governed by the U.S. EPA’s<br />

Surface Water Treatment Rules or SWTR.<br />

Declining Rate Filters<br />

The flow rate will vary with head loss. Each filter operates at the same rate, but can have a<br />

variable water level. This system requires an effluent control structure (weir) to provide<br />

adequate media submergence.<br />

Detention Time<br />

The actual time required for a small amount of water to pass through a sedimentation basin at<br />

a given rate of flow, or the calculated time required for a small amount of liquid to pass through<br />

a tank at a given rate of flow.<br />

Detention Time = (Basin Volume, Gallons) (24 Hours/day)<br />

Flow, Gallons/day<br />

Disinfection<br />

Chlorine is added to the water at the flash mix for pre-disinfection. The chlorine kills or<br />

inactivates harmful microorganisms. Chlorine is added again after filtration for postdisinfection.<br />

Jar Testing (More information later in manual. See the Water Quality Section)<br />

Jar testing traditionally has been done on a routine basis in most water treatment plants to<br />

control the coagulant dose. Much more information, however, can be obtained with only a<br />

small modification in the conventional method of jar testing. It is the quickest <strong>and</strong> most<br />

economical way to obtain good reliable data on the many variables which affect the treatment<br />

process. These include:<br />

� Determination of most effective coagulant.<br />

� Determination of optimum coagulation pH for the various coagulants.<br />

� Evaluation of most effective polymers.<br />

� Optimum point of application of polymers in the treatment train.<br />

� Optimum sequence of application of coagulants, polymers, <strong>and</strong> pH adjustment chemicals.<br />

� Best flocculation time.<br />

WT303� 10/13/2011 TLC 33<br />

(866) 557-1746 Fax (928) 468-0675

pH<br />

Expression of a basic or acid condition of a liquid. The range is from 0-14, zero being the most<br />

acid <strong>and</strong> 14 being the most alkaline. A pH of 7 is considered to be neutral. Most natural water<br />

has a pH between 6.0 <strong>and</strong> 8.5.<br />

Caustic<br />

NaOH (also called Sodium Hydroxide) is a strong chemical used in the treatment process to<br />

neutralize acidity, increase alkalinity, or raise the pH value.<br />

Polymer<br />

A type of chemical, when combined with other types of coagulants, aids in binding small<br />

suspended particles to larger particles to help in the settling <strong>and</strong> filtering processes.<br />

Post-Chlorine<br />

Where the water is chlorinated to make sure it holds a residual in the distribution system.<br />

Pre-Chlorine<br />

Where the raw water is dosed with a large concentration of<br />

chlorine.<br />

Pre-Chlorination<br />

The addition of chlorine before the filtration process will<br />

help:<br />

� Control algae <strong>and</strong> slime growth<br />

� Control mud ball formation<br />

� Improve coagulation<br />

� Precipate iron<br />

Raw Turbidity<br />

The turbidity of the water coming to the treatment plant from the raw water source.<br />

Settled Solids<br />

Solids that have been removed from the raw water by the coagulation <strong>and</strong> settling processes.<br />

Hydrofluosilicic Acid<br />

(H2SiF6) a clear, fuming corrosive liquid with a pH ranging from 1 to 1.5. Used in water<br />

treatment to fluoridate drinking water.<br />

Corrosion Control<br />

The pH of the water is adjusted with sodium carbonate, commonly called soda ash. Soda ash<br />

is fed into the water after filtration.<br />

Zinc Orthophosphate<br />

A chemical used to coat the pipes in the distribution system to inhibit corrosion.<br />

Taste <strong>and</strong> Odor Control<br />

Powdered activated carbon (PAC) is occasionally added for taste <strong>and</strong> odor control. PAC is<br />

added to the flash mix.<br />

WT303� 10/13/2011 TLC 34<br />

(866) 557-1746 Fax (928) 468-0675

Water Quality<br />

Water testing is conducted throughout the treatment process. Items like turbidity, pH, <strong>and</strong><br />

chlorine residual are monitored <strong>and</strong> recorded continuously. Some items are tested several<br />

times per day, some once per quarter <strong>and</strong> others once per year.<br />

Sampling<br />

Collect the water sample at least 6 inches under the surface by plunging the container mouth<br />

down into the water <strong>and</strong> turning the mouth towards the current by dragging the container<br />

slowly horizontal. Care should be taken not to disturb the bottom of the water source or along<br />

the sides. so as not to stir up any settled solids. This would create erroneous results.<br />

Chemical feed <strong>and</strong> rapid mix<br />

Chemicals are added to the water in order to improve the subsequent treatment processes.<br />

These may include pH adjusters <strong>and</strong> coagulants. Coagulants are chemicals, such as alum,<br />

that neutralize positive or negative charges on small particles, allowing them to stick together<br />

<strong>and</strong> form larger particles that are more easily removed by sedimentation (settling) or filtration.<br />

A variety of devices, such as baffles, static mixers, impellers, <strong>and</strong> in-line sprays can be used to<br />

mix the water <strong>and</strong> distribute the chemicals evenly.<br />

Short-Circuiting<br />

Short-Circuiting is a condition that occurs in tanks or basins when some of the water travels<br />

faster than the rest of the flowing water. This is usually undesirable, since it may result in<br />

shorter contact, reaction, or settling times in comparison with the presumed detention times.<br />

Tube Settlers<br />

This modification of the conventional process contains many metal “tubes” that are placed in<br />

the sedimentation basin, or clarifier. These tubes are approximately 1 inch deep <strong>and</strong> 36 inches<br />

long, split-hexagonal shape, <strong>and</strong> installed at an angle of 60 degrees or less.<br />

These tubes provide for a very large surface area upon which particles may settle as the water<br />

flows upwards. The slope of the tubes facilitates gravity settling of the solids to the bottom of<br />

the basin, where they can be collected <strong>and</strong> removed. The large surface settling area also<br />

means that adequate clarification can be obtained with detention times of 15 minutes or less.<br />

As with conventional treatment, this sedimentation step is followed by filtration through mixed<br />

media.<br />

Adsorption Clarifiers<br />

The concept of the adsorption clarifier package plant was developed in the early 1980’s. This<br />

technology uses an up-flow clarifier with low-density plastic bead media, usually held in place<br />

by a screen. This adsorption media is designed to enhance the sedimentation/clarification<br />

process by combining flocculation <strong>and</strong> sedimentation into one step. In this step, turbidity is<br />

reduced by adsorption of the coagulated <strong>and</strong> flocculated solids onto the adsorption media <strong>and</strong><br />

onto the solids already adsorbed onto the media.<br />

Air scouring cleans adsorption clarifiers followed by water flushing. Cleaning of this type of<br />

clarifier is initiated more often than filter backwashing because the clarifier removes more<br />

solids. As with the tube-settler type of package plant, the sedimentation/clarification process is<br />

followed by mixed-media filtration <strong>and</strong> disinfection to complete the water treatment.<br />

WT303� 10/13/2011 TLC 35<br />

(866) 557-1746 Fax (928) 468-0675

Clearwell<br />

The final step in the conventional filtration process, the clearwell provides temporary storage<br />

for the treated water. The two main purposes for this storage are to have filtered water<br />

available for backwashing the filter, <strong>and</strong> to provide detention time (or contact time) for the<br />

chlorine (or other disinfectant) to kill any microorganisms that may remain in the water.<br />

Dried backwash channels on top of a cleaned filter bed.<br />

WT303� 10/13/2011 TLC 36<br />

(866) 557-1746 Fax (928) 468-0675

Pretreatment sedimentation basin, bottom photograph, sludge drying bed with new<br />

grass. Time to turn the sludge over.<br />

WT303� 10/13/2011 TLC 37<br />

(866) 557-1746 Fax (928) 468-0675

Cholera, top <strong>and</strong> bottom photos<br />

WT303� 10/13/2011 TLC 38<br />

(866) 557-1746 Fax (928) 468-0675

EPA Filter Backwash Rule<br />

The U.S. Environmental Protection Agency (EPA) has finalized the Long Term 1 Enhanced<br />

Surface Water Treatment Rule <strong>and</strong> Filter Backwash Rule (LT1FBR) to increase protection of<br />

finished drinking water supplies from contamination by Cryptosporidium <strong>and</strong> other microbial<br />

pathogens.<br />

This rule will apply to public water systems using surface water or ground water under the<br />

direct influence of surface water. This rule will extend protections against Cryptosporidium<br />

<strong>and</strong> other disease-causing microbes to the 11,500 small water systems which serve fewer<br />

than 10,000 people annually.<br />

This rule also establishes filter backwash requirements for certain public water systems of all<br />

sizes. The filter backwash requirements will reduce the potential risks associated with<br />

recycling contaminants removed during the filtration process.<br />

Background<br />

The Safe Drinking Water Act (SDWA) requires the EPA to set enforceable st<strong>and</strong>ards to<br />

protect public health from contaminants which may occur in drinking water. The EPA has<br />

determined that the presence of microbiological contaminants is a health concern. If finished<br />

water supplies contain microbiological contaminants, disease outbreaks may result. Disease<br />

symptoms may include diarrhea, cramps, nausea, possibly jaundice, <strong>and</strong> headaches <strong>and</strong><br />

fatigue. The EPA has set enforceable drinking water treatment requirements to reduce the<br />

risk of waterborne disease outbreaks. Treatment technologies such as filtration <strong>and</strong><br />

disinfection can remove or inactivate microbiological contaminants.<br />

Physical removal is critical to the control of Cryptosporidium because it is highly resistant to<br />

st<strong>and</strong>ard disinfection practice. Cryptosporidiosis may manifest itself as a severe infection that<br />

can last several weeks <strong>and</strong> may cause the death of individuals with compromised immune<br />

systems. In 1993, Cryptosporidium caused over 400,000 people in Milwaukee to experience<br />

intestinal illness. More than 4,000 were hospitalized, <strong>and</strong> at least 50 deaths were attributed<br />

to the cryptosporidiosis outbreak.<br />

The 1996 Amendments to SDWA require the EPA to promulgate an Interim Enhanced<br />

Surface Water Treatment Rule (IESWTR) <strong>and</strong> a Stage 1 Disinfection Byproducts Rule<br />

(announced in December 1998). The IESWTR set the first drinking water st<strong>and</strong>ards to<br />

control Cryptosporidium in large water systems, by establishing filtration <strong>and</strong> monitoring<br />

requirements for systems serving more than 10,000 people each. The LT1FBR proposal<br />

builds on those st<strong>and</strong>ards by extending the requirements to small systems.<br />

The 1996 Amendments also required the EPA to promulgate a Long Term 1 Enhanced<br />

Surface Water Treatment Rule (for systems serving less than 10,000 people) back in<br />

November, 2000 ((1412(b)(2)(C)) <strong>and</strong> also require the EPA to “promulgate a regulation to<br />

govern the recycling of filter backwash water within the treatment process of a public<br />

water system” back in August, 2000 ((1412(b)(14)). The current rule includes provisions<br />

addressing both of these requirements.<br />

What will the LT1FBR require?<br />

The LT1FBR provisions will apply to public water systems using surface water or ground<br />

water under the direct influence of surface water systems.<br />

WT303� 10/13/2011 TLC 39<br />

(866) 557-1746 Fax (928) 468-0675

LT1 Provisions - Apply to systems serving fewer than 10,000 people, <strong>and</strong> fall into the three<br />

following categories:<br />

Turbidity<br />

� Conventional <strong>and</strong> direct filtration systems must comply with specific combined filter<br />

effluent turbidity requirements;<br />

� Conventional <strong>and</strong> direct filtration systems must comply with individual filter turbidity<br />

requirements;<br />

Disinfection Benchmarking<br />

� Public water systems will be required to develop a disinfection profile unless they<br />

perform applicability monitoring which demonstrates their disinfection byproduct<br />

levels are less than 80% of the maximum contaminant levels;<br />

� If a system considers making a significant change to their disinfection practice they<br />

must develop a disinfection benchmark <strong>and</strong> receive State approval for implementing<br />

the change.<br />