EP1639913B1 - Brosse, notamment brosse à dents et procédé de fabrication - Google Patents

Brosse, notamment brosse à dents et procédé de fabrication Download PDFInfo

- Publication number

- EP1639913B1 EP1639913B1 EP20040022614 EP04022614A EP1639913B1 EP 1639913 B1 EP1639913 B1 EP 1639913B1 EP 20040022614 EP20040022614 EP 20040022614 EP 04022614 A EP04022614 A EP 04022614A EP 1639913 B1 EP1639913 B1 EP 1639913B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- active substance

- brush head

- component

- brush

- membrane

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A46—BRUSHWARE

- A46B—BRUSHES

- A46B11/00—Brushes with reservoir or other means for applying substances, e.g. paints, pastes, water

- A46B11/001—Brushes with reservoir or other means for applying substances, e.g. paints, pastes, water with integral reservoirs

- A46B11/0068—Brushes where the reservoir is specifically intended for solid substance that dissolves gradually

-

- A—HUMAN NECESSITIES

- A46—BRUSHWARE

- A46B—BRUSHES

- A46B11/00—Brushes with reservoir or other means for applying substances, e.g. paints, pastes, water

- A46B11/0003—Brushes with reservoir or other means for applying substances, e.g. paints, pastes, water containing only one dose of substance, e.g. single-use toothbrushes

-

- A—HUMAN NECESSITIES

- A46—BRUSHWARE

- A46B—BRUSHES

- A46B11/00—Brushes with reservoir or other means for applying substances, e.g. paints, pastes, water

- A46B11/001—Brushes with reservoir or other means for applying substances, e.g. paints, pastes, water with integral reservoirs

- A46B11/002—Brushes with reservoir or other means for applying substances, e.g. paints, pastes, water with integral reservoirs pressurised at moment of use manually or by powered means

- A46B11/0041—Flexible or deformable reservoirs, e.g. resilient bulbs, compressible tubes

-

- A—HUMAN NECESSITIES

- A46—BRUSHWARE

- A46B—BRUSHES

- A46B11/00—Brushes with reservoir or other means for applying substances, e.g. paints, pastes, water

- A46B11/001—Brushes with reservoir or other means for applying substances, e.g. paints, pastes, water with integral reservoirs

- A46B11/0062—Brushes where the reservoir is specifically intended for being refilled when empty

-

- A—HUMAN NECESSITIES

- A46—BRUSHWARE

- A46B—BRUSHES

- A46B15/00—Other brushes; Brushes with additional arrangements

- A46B15/0091—Container, e.g. bag or box with a collection of various devices

-

- A—HUMAN NECESSITIES

- A46—BRUSHWARE

- A46D—MANUFACTURE OF BRUSHES

- A46D3/00—Preparing, i.e. Manufacturing brush bodies

-

- A—HUMAN NECESSITIES

- A46—BRUSHWARE

- A46B—BRUSHES

- A46B2200/00—Brushes characterized by their functions, uses or applications

- A46B2200/10—For human or animal care

- A46B2200/1066—Toothbrush for cleaning the teeth or dentures

Definitions

- the invention relates to a brush, in particular a toothbrush, and a method for the production thereof according to claim 1.

- Disposable toothbrushes which already contain toothpaste in various ways.

- US 5,346,324 and US 5,909,977 is low-viscosity toothpaste in a reservoir in the grip area and is pushed by a piston in the head area, where it exits through openings in the region of the bristles.

- the disadvantage of this is the difficult dosage of toothpaste, the need to use very thin toothpaste, the cumbersome handle, the frequent drying and congestion of the fluid channel and the difficult to impossible refilling of the reservoir.

- toothbrushes are known in which a predetermined amount of toothpaste is located in a hollow area in the head area and is pressed out prior to cleaning by manual deformation of the head area.

- a slit-like, initially closed opening so that the toothpaste can escape. Multiple use by refilling or exact dosage is not possible.

- the delivery of toothpaste is also associated with relatively great effort. Show similar examples with toothpaste dispensing by manual squeezing FR 2 583 625 or US 5,865,195 , In the US 5,490,530 the outlet openings can be resealed by a slide. The toothpaste is squeezed out by pressing a button located on the underside of the head and reducing the volume of the toothpaste reservoir.

- the user has to act by hand on the brush to release toothpaste at all. Since this requires a certain amount of power and a certain amount of skill for the desired dosage, the known toothbrushes are not easy for anyone to handle.

- a disposable toothbrush in the bristle area contains an encapsulated dose of liquid dentifrice.

- the capsule is broken by contact with the teeth.

- the problem in addition to the restriction to single use, that the detergent can escape even with improper treatment.

- the invention is therefore an object of the invention to provide a brush, in particular a toothbrush, with an active substance available for the Multiple use and / or refilling the active substance is suitable and allows easy handling and simple dosage of the active substance. Furthermore, a method for producing such a brush is to be specified.

- the hollow region is adapted according to the invention to the shape of an active substance element having a defined outer shape.

- the volume of the hollow region is greater than the volume of the active substance element, in particular by 1-2 times, at most 4 times greater. This ensures that the active substance is well bathed in water during use. The release of the active substance happens purely passively by flushing, manual influence of the brush is not necessary.

- the dosage can be adjusted and predefined by a suitable choice of the solubility of the active substance element and the size of the outlet openings and thus likewise not dependent on the skill of the user.

- the brush is so flexible, at least in the area of the hollow area, that the hollow area deforms during intended use, ie during cleaning, in such a way that water is sucked into the hollow area and pushed out again becomes.

- the invention exploits a pumping / suction effect made possible by the flexibility of the hollow region with respect to the solvent water.

- the hollow region is for this purpose preferably adapted to the shape of the active substance element, that this is at least partially spaced from the inner wall and is thus washed in use of water.

- the entire brush head may also have flexible, movable portions, e.g. a flexible brush head front. Due to the flexible deflection of this partial area, the volume of the hollow area is likewise influenced and in turn the pumping / suction effect described above arises.

- the flexibility of the brush head is formed at the point at which the hollow region occupies the largest proportion of the cross section of the brush head. This has the advantage that only a small proportion of the head cross-section must be made flexible. This can be achieved by means of targeted material weakening, e.g. Film hinge, side tunnel, etc., done in the hard component or by combining the hard and soft component. It is also possible to completely form the flexible zone from soft material.

- the active substance element is preferably a solid or a highly viscous, dimensionally stable paste, but may also be an encapsulated liquid, pasty or granular substance, the envelope of which is water-soluble.

- suitable Choice of the solubility or decomposability of the active substance element or its coating manages a well-defined dosage up to a uniform release of active substance during a cleaning process.

- a solid or a highly viscous paste a multiple use of the same active substance element is possible if it is so dimensioned or its solubility or decomposability is chosen so that it survives several typical cleaning operations.

- the active substances are released before, during or after the cleaning process. The risk of drying or clogging of openings does not exist in this case, since any residues can be rinsed off easily after use.

- the active substance element can be refilled by a resealable inlet opening.

- the brush consists of a head part with a cleaning structure, usually bristles, a neck part and a handle part. All sub-elements can be off consist of at least one hard and one or more soft components.

- hard components for example, styrene acrylonitrile (SAN), polyester (PET), polyethylene (PE) polymethyl methacrylate (PMMA), Acrylbuthadienstyrol (ABS), etc., preferably polypropylene (PP) are used.

- the soft component used is a rubber-elastic material such as polyurethane (PUR), preferably a thermoplastic elastomer (TPE or TPU). Hardenings of less than 70 Shore A, preferably less than 40 Shore A, are used in the brush head.

- the bristle field is preferably formed at least partially with conventional bristles such as polyamide (PA) or polyester (PBT) and optionally with rubber-elastic cleaning or massage elements.

- the conventional bristles have, for example, a cylindrical geometry with a diameter of less than 0.25 mm, preferably between 0.1 mm - 0.2 mm and are combined into bundles.

- the rubber-elastic massage or cleaning elements usually have larger diameter with the smallest dimensions in the cross section of 0.5 to 5 mm, preferably 0.5 to 2 mm.

- the hollow area offers at least space for one unit of the active substance, preferably the hollow area offers additional space so that the active substance can be lapped with water and thereby unfold its effect by means of partial or complete dissolution.

- the volume of the hollow region is maximally four times, preferably one to two times larger than the size (the volume in original size) of the active substance.

- the hollow region has a volume of 5 to 1500 mm 3, preferably 100 to 500 mm 3 .

- the active substance can be clamped laterally or vertically in the hollow area.

- projections or other geometric elements in the soft or / and hard component in the hollow area are preferably used for this purpose. This ensures that the active substance during the cleaning process can not be beaten back and forth within the hollow area and at most prematurely break apart.

- the hollow region is preferably generally designed so that the active substance is stably positioned despite continuous degradation in the hollow region.

- the hollow region is preferably provided with a flexible element, preferably made of soft material, which exerts a kind of spring action on the active substance element, for example by passing through an outer wall of the hollow region Insertion of the active substance element is arched outwards.

- the active substance element in original size is fixed with a certain bias in the hollow area.

- the inner shape of the hollow portion follows, with the exception of the above-mentioned projections substantially the geometric shape of the active substance element, preferably with a predefined distance.

- the hollow region can be designed as a slot into which a plate-shaped or foil-shaped active substance can be introduced.

- the active substance can be introduced in a rod-shaped or cylindrical geometry into a correspondingly shaped hollow region.

- the hollow area lies in the plan view of the cleaning structure, preferably within the bristle field, if conventional bristles are present. This makes it possible for the hollow region to be produced with a thin wall, but still enough conventional bristles can be anchored around the hollow region with a certain anchoring depth that is technically determined. Cleaning elements made of soft component, which require less head volume or anchoring depth than conventional bristles for anchoring, are preferably formed directly above the hollow area. In addition, conventional bristles require the hard component for secure anchoring. Since the hollow region on the bristle-carrying side of the brush head is preferably delimited by a membrane of soft material, it is technically very difficult to anchor conventional bristles in this area.

- the hollow region is bounded by a wall of hard and / or soft component, but preferably at least in regions by soft component, since in this way the abovementioned flexibility can be achieved in a simple manner.

- Bristle anchoring advantages are found when the hollow area is in a region adjacent to the brush head, e.g. in the brush neck or in the transition between the brush neck and the brush head, which comes into contact with water.

- This refinement has the advantage that consideration must not be given to the hollow region within the brush head with respect to the anchoring of the bristles. The fact that the active substance does not escape where it generally has the best effect, ie in the head area, is accepted.

- the hollow region preferably has two types of openings, namely at least one outlet opening for the entry of water, for the release of the active substance dissolved in water and for the rinsing out of the hollow area after use under the tap.

- at least one insertion opening for introduction of the active substance by the user is additionally present.

- the introduction opening is larger in the open state than an outlet openings.

- the insertion opening is preferably located on the brush head back and the outlet openings on the brush head front.

- Alternative design variants show the insertion openings on the brush head side.

- the outlet openings may alternatively / additionally on the side and / or back of the Brush head created.

- the insertion opening is preferably reclosable. But it can also serve as an outlet opening and does not complete the hollow area completely sealed.

- the insertion opening may be formed by means of a removable or head-integrated lid or closure, e.g. by means of a molded directly on the head film hinge.

- a membrane of soft material with a corresponding opening, e.g. with one or more crossed slots, which corresponds to the size of the active substance element, as a resealable element.

- the membrane can simultaneously represent a flexible wall of the hollow area and / or serve as a carrier of cleaning / massage elements.

- slots other geometric elements may be provided which allow the introduction of the active substance element and prevent its escape as far as possible, e.g. an expandable hole in the membrane that is smaller than the active substance element.

- this has a thickness of less than 3 mm, preferably a thickness of 0.7 - 1.5 mm.

- 2 to 6 slots are preferably used as the introduction opening.

- the length of the slots for toothbrushes is 3 - 15 mm, preferably around 6 - 10 mm.

- the introduction opening may have a securing device which prevents or at least impedes the falling out of the active substance during use.

- the membrane is formed with slits or a funnel such that the introduction of the active substance takes place with little pressure (for example 10 to 300 g), but falling out by means of eg a funnel-shaped geometry in the opening area requires more pressure.

- additional locking or securing elements are also possible.

- the insertion opening may still be closed during the first use (first opening safeguard or seal).

- first opening safety device can be broken by the user, e.g. by cutting thin residual connections within the prefabricated slots.

- the outlet openings allow a continuous, but limited exit of the active substance dissolved in water.

- the number of openings and their size (total surface of the outlet opening) and the water solubility of the active substance determine the actual exit of the active substance dissolved in water. Since the water solubility of the active substance is rather a resulting size, the outlet openings (number and size) of the water solubility of the active substance are adjusted in order to determine the range of the active substance during use.

- the dissolution of the active substance element can also serve as a time indicator for the (total) cleaning time that has been carried out so far.

- a single outlet opening preferably does not fall below a minimum area of 0.5 mm 2 . Because smaller openings can easily pollute and thus affect the fluid exchange. Moreover, it is advantageous if the user examines the size of the hollow substance still existing active substance element through the outlet openings and possibly decide whether the active substance should be topped up. For these reasons, surfaces of 0.5 to 100 mm 2 are preferably used for the outlet openings, preferably 1 to 20 mm 2 . This ensures accurate dosing and prevents the active substance or fragments of the active substance element from being able to leave the hollow region in an uncontrolled manner.

- the individual outlet openings on a brush head can have different sizes (areas) in order to weight outlet quantity and outlet location.

- individual groups of outlet openings are provided at designated locations on the brush head.

- the exit of the active substances at different points of the bristle field with respect to quantity and location can be controlled.

- an interaction between the active substance and especially in combination anticipated active bristles arise.

- one to five groups (clusters) are formed by outlet openings.

- These groups of outlet openings may also be positioned asymmetrically on the brush head.

- the different groups of outlet openings are preferably manufactured in one operation from the same material.

- outlet openings when the outlet openings are embedded in the rubber-elastic material, this is served from an injection point for all groups, ie the material side, these groups are interconnected.

- the outlet openings can be designed so that they have geometric elements which the surface in the vicinity of the outlet opening Increase to keep the active substance as possible in the brush head.

- a substantially funnel-shaped or at least outwardly opening geometry can be used. This will additionally one easy cleaning of the hollow area after use under the faucet favors. Additional cleaning and massage elements in the area of the outlet openings have the same advantage.

- sponge-like and / or holey soft elements can be placed in the region of the outlet openings, which also contribute to the better retention of the active substance.

- the outlet openings can be formed in the hard material and / or in the soft material of the brush head. However, they are preferably integrated into the above-described membrane made of soft material. In this case, it preferably has a thickness of less than 3 mm, preferably from 0.7 to 1.5 mm.

- the hollow region is preferably bounded by membranes of soft material as described above.

- These membrane (s) are flexible to adapt to the environment (gums, teeth, oral cavity, etc.) during use and to exert a certain pumping and suction effect on the hollow area during the cleaning process with the plastering pressure on the membrane. These effects can be enhanced by a domed shape of the membrane. Together with the outlet openings, the membrane can form a kind of expandable network structure.

- cleaning and massage elements made of soft material are preferably formed on the flexible membranes which delimit the hollow region.

- a part of the brush head with a flexible membrane and this design with cleaning and / or massage elements made of soft material can be advantageously used for brushes, which have no hollow area for active substances, but eg only an empty or no hollow area .

- the membrane and the cleaning and / or massage elements are manufactured in one operation, in particular by injection molding. It succeeds the Production of a brush with a particularly elastic suspended cleaning / massage structure.

- the following preferred embodiments also apply to brushes without a hollow area, but with a membrane provided with a cleaning / massage structure.

- cleaning and / or massage elements which are located in the region of the outlet openings, are aligned parallel to the Entformungscardi of the brush head.

- Fabrication technically complex, but effective in use are cleaning or massage elements, which are aligned at a certain angle, preferably substantially perpendicular to the possibly curved membrane surface.

- the cleaning or massage elements which are located in the region of the outlet openings, are preferably less long than the conventional bristles in their environment, so that during use in the end of the cleaning or massage elements can form a kind of reservoir for the active substance dissolved in water.

- the cleaning and massage elements can also have outlet openings, which is the case, for example, with straw-shaped bristles, lamellae and warts with holes. These have the advantage that they are the active substance directly to the Can bring the job site. By capillary action, the active substance can travel a relatively long way in this case.

- the membrane can deliver or pass active substances even in the submicroscopic range, e.g. through microporosity, semipermeability.

- the active substance element is preferably a solid which, in use, at least partially dissolves in the water.

- the active substance element in solid form is shaped in the form of a tablet, pill, a rod-shaped element, plate or foil corresponding to the hollow region.

- a paste or kneadable mass having a dynamic viscosity higher than conventional commercially available pastes (toothpaste) may also be employed.

- a spatially defined shape can be produced and the active substance stay as long as possible in the hollow area.

- the paste can harden after introduction into the hollow region in order to deliver the active substance in various applications.

- the active substance can be easily portioned by the user.

- the solid is already pre-portioned in the sales packaging.

- the paste can be simply portioned by the consumer due to the given volume of the hollow area.

- the active substances can be used together with conventional cleaning agents or independently of these.

- the brush can generally also be used without active substances with conventional cleaning agents.

- both the single use of an active substance element as well as the multiple use is possible.

- use of the brush consumes a portion of the active substance.

- the active substance can be reintroduced before each use or even occasionally used.

- use of the brush consumes only a part of the active substance.

- the user recognizes when the active substance is used up, and can then replenish it by means of a new portion of the active substance.

- concentration or amount of the active substance is set much lower in the intended single use than in multiple use.

- the concentration corresponds approximately to the concentration of the active ingredients of conventional pastes.

- the corresponding concentration is increased by a multiple.

- the range / duration of use of the active substance is also influenced by the water solubility and water circulation / openings.

- the system hollow area, openings and water solubility of the active ingredient can be adjusted so that the user can be displayed a certain period of use (Time indicator).

- the properties for single use are chosen so that the active ingredient is used up after 3 minutes cleaning time.

- the active ingredient is depleted after a typical 3 month use period, indicating that the entire brush should be replaced due to wear.

- Under the active substance at most even a lettering (eg, 'Change') are hidden, which is exposed after the exhaustion of the active substance and visible to the user and makes the user aware of the upcoming change of the active substance or the recommended change of the brush.

- the active substance element can be provided with additional recesses, concave or convex elements on the surface.

- the color of the active substance element is preferably chosen so that it differs significantly from brush head and the user can easily judge the consumption of the active substance.

- the solubility of the active substance depends on the water temperature used.

- the user can control the delivery of the amount of active substance by controlling the water temperature.

- the delivered amount of active substance in a temperature window of 10 ° - 40 ° increases the delivery significantly.

- the active substance is incorporated in an advantageous development in an effervescent tablet or paste with effervescent effect. This additional function allows the user to determine during use whether the active substance already used up or still present in the hollow area without removing the brush from the mouth.

- the brush is packaged such that the package unambiguously shows the user brush and active substance.

- the active substance is preferably distributed in predefined portions next to the brush head.

- the active substance is preferably provided in a part of the packaging which is independent of the opening of the brush packaging.

- a first portion of the active substance is preferably already placed in the sales packaging in the hollow region of the brush head.

- the brush head is placed in the package so that the inlet and outlet openings can be shown.

- a so-called double blister offers itself, which allows the user to view both brush head sides.

- only the active substance can be provided again in predefined portions as a so-called replacement package (refill).

- the active substance can also be provided in a dispenser for portionwise delivery.

- the brush head can be introduced in this embodiment variant in the dispenser and the active substance are then donated mechanically through the insertion opening into the hollow area.

- Injection of the membrane with any existing cleaning and massage elements can be performed before or after the onset of conventional bristles.

- the injection points for the membrane and any cleaning or massage elements placed on it should be selected as far as possible within the head or in the neck region of the brush. At most, areas of soft material can be made in the handle of the toothbrush in the same operation with the same material.

- the cleaning or massage elements which are arranged in the region of the membrane, made with the same material in one operation with the membrane.

- a soft component with a Shore A hardness of less than 70, preferably less than 40

- stiffness of the cleaning or massage elements cleaning effect, massage effect

- the connection of the membranes of soft material to the hard component of the brush head is preferably carried out in multi-component injection molding.

- a geometry element of 0.1 to 2 mm depth / length is preferably formed on the predominant region of the connection of the membrane to the hard component for better connection of the membrane.

- the first introduction of the active substance into the brush head may be provided by the consumer during the first use or during the manufacturing process of the brush.

- the methods with a two-part brush head in particular by means of AFT, are particularly suitable.

- the active substance is placed in the toothbrush head before the bristled AFT plate is permanently welded to the toothbrush handle.

- the AFT procedure is generally appropriate for this, between the bristled AFT plate and the toothbrush handle to place additional component or element.

- FIG. 4 shows an embodiment, which does not show that an active substance element is injected into the cavity.

- the embodiments according to the FIGS. 24 to 27 , 30 to 32, 35 and 36 are not covered by the scope of the claims.

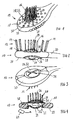

- Fig. 1-4 show various views of a head portion 10 of a toothbrush according to the invention.

- a cleaning structure 12 consisting of conventional bristles 14, summarized in bundles, and soft elastic cleaning elements 16 attached. Instead of the conventional bristles 14, in some cases only the anchoring areas of the bristle bundles 38 are indicated.

- the head region 10 consists of a hard component 30 that is solid (see also FIG Fig. 5-7 ) and in particular the conventional bristles 14 are anchored with a certain anchoring depth.

- a circular or elliptical recess 31 which is circular or elliptical in plan view and which is covered on the front and rear sides by a flexible wall 28 in the form of an elastic membrane 28 or 26 made of soft material 32.

- a hollow region 22 is formed within the head region 10.

- the soft elastic structure 16 is anchored in the front membrane 28.

- the membrane and the soft elastic structure are formed together in one manufacturing step from the same material from the same injection point.

- the membrane 26 on the back 20 has two crossed slots, which serve as a reclosable insertion opening 34 for an active substance element 24.

- the front side membrane 28 has outlet openings 36 through which water can enter the hollow region 22 and enriched with active substance can escape again.

- the wall region of the hollow region 22 formed of soft material 32 forms a flexible zone 29. Under cleaning pressure, the toothbrush deforms in this zone in such a way that water is sucked into the hollow region 22 and pushed out again.

- the membranes can also be made of a hard component with a correspondingly small wall thickness in order to achieve the necessary flexibility.

- a soft component has advantages insofar as the anchoring of cleaning elements in a thin hard material layer is problematic in terms of manufacture, but the simultaneous injection of soft elastic elements onto a soft membrane is unproblematic.

- a combination of hard and soft materials may form the membrane.

- the flexible elements of the membrane and cleaning elements are made of soft material.

- the hard component forms only structuring, stabilizing elements of the membrane or merely serves as a production-related material compound.

- the hollow portion 22 is adapted to the shape of an active substance element 24 that this is at least partially spaced from the inner wall 23.

- an active substance element 24 that this is at least partially spaced from the inner wall 23.

- protrusions 40 that point inward from the flexible membranes 26, 28 are formed. Due to the flexibility of the membranes 26, 28, the active substance element 24 is well positioned even as the resolution progresses.

- outlet openings are each between the soft elastic Cleaning elements 16 within the front side membrane 28.

- the membrane surface thus has a net-like perforated structure.

- Fig. 8, 9 show another example of a hard and soft component 30, 32 existing toothbrush.

- the soft component 32 forms a flexible zone 29, which connects the two otherwise separate parts of the brush head of hard component 30 together.

- the whole brush head front part can deflect relative to the brush head rear part.

- the hollow region 22 is delimited, as in the above examples, front and rear and additionally also laterally by thin material layers (membranes 26, 28) of soft component 32 and in the longitudinal direction by the hard component 30.

- a compound of hard component can additionally be guided, which makes it possible to produce the two brush head segments from hard component in one work step.

- this connection is made very thin, so that the flexibility is not adversely affected.

- conventional bristles 14 are anchored in the hard component 30, while the soft component is provided with soft-elastic cleaning elements 16.

- the insertion opening 34 is as in Fig. 1-7 designed as a cross slot.

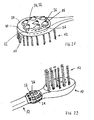

- the flexible zone 29 formed of soft material 32 occupies the entire brush tip and is made substantially circular in plan view. In a concentric arrangement, it carries here from inside to outside soft elastic cleaning elements 16, outlet openings 36 and conventional bristles 14 (or their anchoring areas). Toward the neck region 52, a conventional bristle field embedded in the hard component 30 adjoins. The outlet openings 36 are so large that the underlying hollow area 22 is visible.

- the part of the brush head formed from the hard component 30 is in one piece. However, it has recesses in such a way that a flexible zone 29 connected to the rear side 20 with three regions (clusters) 44 is formed by outlet openings 36. These are located at the top and on the sides of the head portion 10 in a respective outwardly curved flexible wall / membrane, preferably made of soft material 32.

- the remaining portion of the head part 10 is bristled on the front side 18 with conventional bristles 14; On the back there is again a cross-shaped insertion opening as in Fig. 5-7 ,

- Fig. 16-21 show examples of different shapes of the flexible zone 29 in a toothbrush according to the invention in front and rear view ( Fig. 16-19 ) or only in front view ( Fig. 20, 21 ). On the back there is one again in all examples Phillips-shaped insertion opening 34 as in Fig. 5-7 (only partially shown).

- the flexible zone 29 has three laterally arranged, gill-like regions 46 (or clusters 44) with lamellar cleaning / massage elements 16 and outlet openings 36 arranged therebetween.

- the regions 46 are connected to one another at the rear via a material bridge 32 (see FIG Fig. 17 ).

- the lamellae / fish gills are less pronounced and only two lateral clusters 44 are present.

- the outlet openings 36 are uniformly distributed over the lateral edge of the head portion 10 and each knob-like surrounded by soft material, so that also here by the knobs during cleaning results in a massage effect.

- Fig. 22, 23 show a brush in front and rear view, in which the outlet openings 36 are located on the back facing away from the bristle 20 and thus the active substance is released mainly at the back 20.

- the back 20 is largely made of hard material 30 which is broken like a net and the view of the hollow portion 22 within the brush head 10 releases.

- the hollow portion 22 extends substantially over the entire surface of the head portion 10. The sufficient flexibility of the wall of the hollow portion is achieved by a correspondingly thin material thickness and through the openings or outlet openings 36.

- a portion of the hollow portion 22 is covered on the back by a membrane 26 made of soft material 32, in which are arranged radially, serving as an insertion opening 34 slots.

- the brush head 10 consists of two parts (tip and neck-side region) of a hard component 30, which are interconnected by a flexible zone 29 of soft material 32 or a combination of hard and soft material.

- a hollow portion 22 is formed in the form of a tubular recess with an elliptical cross-section.

- the hollow region 22 is limited to the front side 18 by three webs 48 made of soft material 32. Between the webs 48 are two outlet openings 36 with a total width of about half the head width.

- the underside of the hollow portion 22 is the entire surface of soft material 32 or a combination of hard and soft material.

- Soft elastic cleaning elements 16 are arranged on the webs 48, conventional bristles 14 are anchored on the hard areas at the top and in the neck area. Between the webs 48 and the bottom 66 of the hollow portion 22 an elliptical insertion opening 34 for the active substance element 24 is formed. This has essentially the shape of a cylinder with elliptical cross-section and rounded edges. The active substance element 24 is clamped between the webs and the bottom 66. Laterally, however, it is spaced from the inner wall of the hollow portion 22, so that it is washed around there and in the region of the outlet openings 36 of water. Due to the spatial shape with a substantially two-part hard component 30 and the parts connecting flexible zone 29 made of soft material 32 of the brush head is particularly flexible. Alternatively, the webs 48 can also be made of the hard component 30 and the tip and the neck area hinge-like connect; the flexibility is ensured in this case by a correspondingly thin wall thickness of the webs 48.

- Fig. 25-27 show variations of the example Fig. 24 also with a substantially two-part hard component 30 and a flexible zone 29 connecting the parts made of soft component 32 or a combination of hard and soft component, in which the hollow portion 22 is accommodated for receiving the active substance element 24.

- the hollow portion 22 and the active substance element 24 themselves are cylindrical with a circular cross section.

- the introduction opening 34 is also circular and may have a smaller diameter than the hollow area 22 itself, so that the active substance element 24 in the hollow area 22 can be at least partially washed around.

- the hollow region 22 is substantially surrounded by soft material 32 in its radial direction with the exception of the outlet openings 36 in the front-side membrane 28.

- Fig. 25-27 show variations of the example Fig. 24 also with a substantially two-part hard component 30 and a flexible zone 29 connecting the parts made of soft component 32 or a combination of hard and soft component, in which the hollow portion 22 is accommodated for receiving the active substance element 24.

- the hollow portion 22 and the active substance element 24 themselves are

- Fig. 27 shows an analogous example with an elongated in the longitudinal direction of the brush head elastic zone 29 in which a substantially cuboid hollow portion 22 is formed. This is adapted to a plate-shaped or foil-shaped active substance element 24.

- the hollow region 22 on the rear side 20 of the brush head is covered by a flexible membrane 26 of soft material 32 and otherwise formed within the hard component 30.

- the outlet openings 36 are formed on the membrane 26 within knob-shaped or funnel-like elevations, which can simultaneously act as cleaning or massage elements 16, in particular for the palate and tongue.

- the existing of the hard component 30 front 18 can thus be bristled conventionally above the hollow portion 22.

- a combination of this embodiment with a previously shown flexible membrane on the front of the brush head is also conceivable.

- Fig. 29 shows a toothbrush, wherein the hollow portion 22 is formed by a cage-like, adapted to a spherical or ellipsoidal shape of the active substance element thickening in the neck region 52.

- This has a plurality of outlet openings 36, through which the hollow portion 22 is visible.

- the boundary of the hollow region may be formed of hard and / or soft component, resulting in the latter case, a damping zone in the neck region 52.

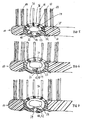

- Fig. 30-33 show schematically different production methods for brushes according to the invention.

- the toothbrush is made of two parts consisting of hard and / or soft component 30 by injection molding, on the one hand, the bristle-side upper half of the brush head and the the rear cover 54 is formed in the upper half.

- a recess for the active substance element 24 is formed, which is later closed with the cover 54 to form the hollow region 22.

- At the upper half of the outlet openings 36 and optionally cleaning elements 16 are formed of soft component 32. Conventional bristles are anchored laterally from the cleaning elements 16 by conventional or in-mold tufting.

- On the cover 54 further outlet openings 36 are formed in the hard component 30.

- the lid 54 may include a membrane of soft component, in which the outlet openings are formed in knob-like elevations. Lid 54 and remaining brush head are then connected to the inclusion of a flat active substance element 24 releasably (snapping, sliding, locking, etc.) or non-detachable (gluing, welding, positive locking, etc.).

- the toothbrush is also made of two parts of a hard and / or soft component by injection molding.

- the brush head back half of the brush head has a plate-shaped recess which forms a cavity 22 in the assembled state with a support plate 56.

- the support plate is made including openings which are closed in a further injection molding step with soft component 32 to form a membrane 26 and possibly soft elastic cleaning elements 16 of soft component.

- the conventional bristles 14 are then anchored in the support plate 56.

- the support plate 56 can also be bristled in the Anchor Free Tufting process, which has the advantage that the support plate can be made thinner.

- the carrier plate is then solvable (Snapping, pushing, locking, etc.) or non-detachable (gluing, welding, positive locking, etc.) connected to the remaining toothbrush, wherein an active substance element 24 is enclosed in the cavity 22.

- Fig. 32 shows a combination of the examples FIGS. 30 and 31 with a three-part (annular body, support plate 56 and back cover 54) existing brush head.

- Fig. 33 shows another example in which the active substance is used in the manufacture of the toothbrush in the hard component 30 and over-injected with the soft component 32.

- a cavity 22 is formed with a flexible wall in the form of a thin membrane 26 of soft component 32.

- openings 36 for the entry and exit of water or water-soluble active substance are present.

- the flexibility of the wall of the hollow portion 22 results from the choice of a wall material having a certain elasticity, particularly by having at least one membrane of soft material 32, and / or by the overall bending elasticity of the hard and / or soft material Brush. As long as the sufficient contact with water or the sufficient dissolution of the active substance is ensured, it is sufficient if the pumping / suction effect or volume change of the hollow region is only slightly or not at all due to the plastering pressure.

- FIGS. 34 and 35 show a self-explanatory package 58 for a toothbrush with active substance, in addition to a matched to the brush shape recess 60 a detachable area, each with an active substance element 24 is present. The user therefore immediately recognizes which product it is.

- Fig. 36 shows a domestic brush with also a head, neck and handle portion 10, 52, 62.

- a hollow portion 22 which is reclosable on the cleaning structure 12 side facing away by a flap 64 and can take an active substance element 24.

- the flap 64 In the flap 64 are the outlet openings for the dissolved active substance.

- a solid soap is preferably used as the active substance element. All previously shown design variants can be adopted analogously for the dishwashing brush. The dimensions given are to be adjusted in proportion to the dimensions of the cleaning brush head.

- a brush with a flexible membrane in the head part which carries cleaning and / or massaging elements, even without an underlying hollow area advantages, especially because of the flexible suspension of the cleaning and / or massaging elements.

- All shown Examples can be modified accordingly, for example by no hollow area or a hollow area not communicating with the outside world being provided.

- the in Fig. 24-27 shown examples in which the flexible zone 29 maintained, but with respect to the uptake and release of active substance has no function.

Claims (23)

- Procédé de fabrication d'une brosse à dents, selon lequel un corps de brosse comprenant une partie de tête, d'encolure et de manche est fabriqué en un composant dur (30), un espace creux (22) étant formée dans la partie de tête ou d'encolure, dans laquelle un élément à substance active (24), qui se dissout au moins en partie lors de l'utilisation avec de l'eau en libérant une substance active, est ensuite fixé, caractérisé en ce que la substance active est incorporée dans une matrice plastique et injectée dans l'espace creux (22) pour former l'élément à substance active (24).

- Procédé selon la revendication 1, caractérisé en ce que l'élément à substance active (24) est au moins partiellement enrobé lors d'une étape supplémentaire.

- Procédé selon la revendication 1 ou 2, caractérisé en ce que l'élément à substance active (24) est enrobé avec un composant souple (32).

- Procédé selon l'une quelconque des revendications 1 à 3, caractérisé en ce que des ouvertures de sortie (36) pour la substance active sont formées dans le composant dur (30) et/ou éventuellement dans le composant souple (32), et en ce que l'élément à substance active (24) isole les ouvertures de sortie (36) dans le composant dur (30) du composant souple (32).

- Procédé selon l'une quelconque des revendications 1 à 4, caractérisé en ce que des éléments de massage et/ou de nettoyage (16) sont agencés sur une paroi flexible (26, 28), par laquelle l'espace creux (22) est au moins partiellement délimitée et qui se courbe au moins partiellement vers l'extérieur, lesdits éléments étant également constitués du composant souple (32), de préférence fabriqués avec la paroi flexible (26, 28) en une opération et à partir du même matériau, les ouvertures de sortie (36) étant de préférence formées dans la paroi flexible (26, 28) entre les éléments de massage et/ou de nettoyage (16) et/ou dans les éléments de massage et/ou de nettoyage (16).

- Procédé selon la revendication 5, caractérisé en ce que la liaison de la paroi flexible (26, 28) sur le composant dur de la tête de brosse a lieu par moulage par injection multi-composant.

- Procédé selon l'une quelconque des revendications 1 à 6, caractérisé en ce que la partie de tête est fabriquée avec une substance active moulée par injection par un procédé de moulage par injection multi-composant.

- Procédé selon l'une quelconque des revendications 1 à 7, caractérisé en ce que la matrice plastique est reliée au composant dur (30) par un procédé de moulage par injection consécutif.

- Procédé selon l'une quelconque des revendications 1 à 8, caractérisé en ce que des contre-dépouilles pour l'ancrage de la substance active sont formées par moulage par injection.

- Procédé selon l'une quelconque des revendications 1 à 9, caractérisé en ce que l'élément à substance active (24) est muni de retraits supplémentaires, d'éléments concaves ou convexes sur la surface, pour agrandir la surface.

- Procédé selon la revendication 1, caractérisé en ce que le corps de brosse est formé avec un évidement formant l'espace creux (22) et un élément de couvercle (54, 56) logeant de préférence de manière ajustée sur l'évidement, formé à partir du composant dur (30), en ce qu'après l'injection de la substance active et de la matrice plastique dans l'évidement, l'élément de couvercle (54, 56) est placé sur l'évidement.

- Procédé selon la revendication 11, caractérisé en ce que l'élément de couvercle (54, 56) est muni d'une structure de nettoyage (12) comprenant notamment des poils (14).

- Procédé selon l'une quelconque des revendications 1 à 12, caractérisé en ce que l'espace creux (22) est formé au moyen de noyaux de moule/coulisseaux sur le côté de la tête portant les poils et/ou sur le côté arrière de la tête de brosse.

- Procédé selon l'une quelconque des revendications 1 à 13, caractérisé en ce que l'espace creux (22) est formé au moyen de noyaux de moule/coulisseaux latéraux pour la formation d'un tunnel transversal au travers de la tête de brosse.

- Procédé selon la revendication 11 ou 12, caractérisé en ce que la brosse à dents est fabriquée par un procédé de moulage par injection à partir d'une moitié supérieure du côté des poils de la tête de brosse et d'un couvercle arrière (54), qui sont constitués d'un composant dur et/ou souple (30), le couvercle (54) et le reste de la tête de brosse étant ensuite reliés avec inclusion d'un élément à substance active (24).

- Procédé selon la revendication 15, caractérisé en ce que les ouvertures de sortie (36) et éventuellement les éléments de nettoyage (16) sur la moitié supérieure de la tête de brosse sont formés à partir des composants souples (32).

- Procédé selon la revendication 15 ou 16, caractérisé en ce que des poils classiques sont ancrés à côté des éléments de nettoyage (16) par bourrage classique ou In Mould Tufting.

- Procédé selon l'une quelconque des revendications 15 à 17, caractérisé en ce que des ouvertures de sortie supplémentaires (36) sont formées dans le composant dur (30) sur le couvercle (54).

- Procédé selon l'une quelconque des revendications 15 à 17, caractérisé en ce que le couvercle (54) contient une membrane formée à partir du composant souple (32), dans laquelle des ouvertures de sortie supplémentaires (36) sont formées.

- Procédé selon l'une quelconque des revendications 1 à 19, caractérisé en ce que la brosse à dents est fabriquée par un procédé de moulage par injection à partir de deux parties, qui sont constituées d'un composant dur et/ou souple (30), la moitié du côté arrière de la tête de brosse formant à l'état composé l'espace creux (22) avec une plaque support (56), en ce que des poils classiques (14) sont ancrés dans la plaque support (56), et en ce que la plaque support (56) est ensuite reliée au reste de la brosse à dents, l'élément à substance active (24) étant incorporé dans l'espace creux (22).

- Procédé selon la revendication 20, caractérisé en ce que la plaque support (56) est fabriquée en incluant des ouvertures qui sont fermées lors d'une étape de moulage par injection supplémentaire avec le composant souple (32) pour la formation d'une membrane (26) et éventuellement également avec des éléments de nettoyage élastiques souples (16) formés à partir du composant souple (32).

- Procédé selon la revendication 20 ou 21, caractérisé en ce que la plaque support (56) est munie de poils par le procédé Anchor Free Tufting.

- Procédé selon la revendication 22, caractérisé en ce que la substance active est placée dans la tête de brosse à dents avant que la plaque munie de poils par le procédé AFT ne soit soudée avec le manche de la brosse à dents de manière inséparable.

Priority Applications (12)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT04022614T ATE534314T1 (de) | 2004-09-22 | 2004-09-22 | Bürste, insbesondere zahnbürste, und verfahren zu deren herstellung |

| EP20040022614 EP1639913B1 (fr) | 2004-09-22 | 2004-09-22 | Brosse, notamment brosse à dents et procédé de fabrication |

| EP10011705.0A EP2335521B1 (fr) | 2004-09-22 | 2005-09-07 | Brosse, en particulier brosse à dents |

| US11/662,486 US8109686B2 (en) | 2004-09-22 | 2005-09-07 | Brush, in particular toothbrush, and associated production method |

| EP15187837.8A EP3000351B1 (fr) | 2004-09-22 | 2005-09-07 | Procédé de fabrication d'une brosse à dents et brosse à dents |

| EP05785195.8A EP1796507B1 (fr) | 2004-09-22 | 2005-09-07 | Brosse, en particulier brosse à dents, et procédé de production de cette brosse |

| PCT/EP2005/009615 WO2006032367A1 (fr) | 2004-09-22 | 2005-09-07 | Brosse, en particulier brosse a dents, et procede de production de cette brosse |

| US13/341,212 US8408833B2 (en) | 2004-09-22 | 2011-12-30 | Brush, in particular toothbrush, and associated production method |

| US13/779,032 US8851781B2 (en) | 2004-09-22 | 2013-02-27 | Brush, in particular toothbrush, and associated production method |

| US14/458,710 US9538837B2 (en) | 2004-09-22 | 2014-08-13 | Brush, in particular toothbrush, and associated production method |

| US15/371,578 US10390606B2 (en) | 2004-09-22 | 2016-12-07 | Brush, in particular toothbrush, and associated production method |

| US16/445,757 US10856647B2 (en) | 2004-09-22 | 2019-06-19 | Brush, toothbrush, and associated production method |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP20040022614 EP1639913B1 (fr) | 2004-09-22 | 2004-09-22 | Brosse, notamment brosse à dents et procédé de fabrication |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1639913A1 EP1639913A1 (fr) | 2006-03-29 |

| EP1639913B1 true EP1639913B1 (fr) | 2011-11-23 |

Family

ID=34926668

Family Applications (4)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP20040022614 Active EP1639913B1 (fr) | 2004-09-22 | 2004-09-22 | Brosse, notamment brosse à dents et procédé de fabrication |

| EP15187837.8A Active EP3000351B1 (fr) | 2004-09-22 | 2005-09-07 | Procédé de fabrication d'une brosse à dents et brosse à dents |

| EP10011705.0A Not-in-force EP2335521B1 (fr) | 2004-09-22 | 2005-09-07 | Brosse, en particulier brosse à dents |

| EP05785195.8A Not-in-force EP1796507B1 (fr) | 2004-09-22 | 2005-09-07 | Brosse, en particulier brosse à dents, et procédé de production de cette brosse |

Family Applications After (3)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP15187837.8A Active EP3000351B1 (fr) | 2004-09-22 | 2005-09-07 | Procédé de fabrication d'une brosse à dents et brosse à dents |

| EP10011705.0A Not-in-force EP2335521B1 (fr) | 2004-09-22 | 2005-09-07 | Brosse, en particulier brosse à dents |

| EP05785195.8A Not-in-force EP1796507B1 (fr) | 2004-09-22 | 2005-09-07 | Brosse, en particulier brosse à dents, et procédé de production de cette brosse |

Country Status (4)

| Country | Link |

|---|---|

| US (6) | US8109686B2 (fr) |

| EP (4) | EP1639913B1 (fr) |

| AT (1) | ATE534314T1 (fr) |

| WO (1) | WO2006032367A1 (fr) |

Cited By (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US8240937B2 (en) | 2002-09-05 | 2012-08-14 | Colgate-Palmolive Company | Oral care implement with bead retention |

| US8282298B2 (en) | 2008-06-26 | 2012-10-09 | Colgate-Palmolive Company | Oral care implement |

| RU2465797C2 (ru) * | 2008-06-25 | 2012-11-10 | Колгейт-Палмолив Компани | Инструмент для ухода за полостью рта (варианты) |

| US8398326B2 (en) | 2010-03-04 | 2013-03-19 | Colgate-Palmolive Company | Fluid dispensing oral care implement |

| US8449211B2 (en) | 2002-09-05 | 2013-05-28 | Colgate-Palmolive Company | Oral care toothbrush |

| US8506196B2 (en) | 2010-02-26 | 2013-08-13 | Colgate-Palmolive Company | Fluid delivery system for an oral care implement |

| US8517728B2 (en) | 2007-01-24 | 2013-08-27 | Colgate-Palmolive Company | Oral care implement having fluid delivery system |

| US8734042B2 (en) | 2010-03-31 | 2014-05-27 | Colgate-Palmolive Company | Oral care implement with rapid flavor release |

| US8747005B2 (en) | 2008-06-04 | 2014-06-10 | Colgate-Palmolive Company | Oral care implement with cavitation system |

| US8806695B2 (en) | 2002-08-09 | 2014-08-19 | Colgate-Palmolive Company | Oral care implement having flexibly supported cleaning elements extending in opposite directions |

| US9402700B2 (en) | 2011-03-09 | 2016-08-02 | Colgate-Palmolive Company | Interdental cleaning device |

| CN104095391B (zh) * | 2007-02-22 | 2016-08-17 | 高露洁-棕榄公司 | 牙刷 |

| US9554641B2 (en) | 2012-10-26 | 2017-01-31 | Colgate-Palmolive Company | Oral care implement |

Families Citing this family (75)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| HU227090B1 (hu) * | 2006-11-21 | 2010-06-28 | Istvan Piller | Helyben keletkezõ szén-dioxiddal mûködõ fog- és ínytisztító szerkezet |

| US8075216B2 (en) * | 2007-01-25 | 2011-12-13 | Colgate-Palmolive Company | Oral care implement housing an oral care agent |

| DE102007021314A1 (de) * | 2007-05-07 | 2008-11-13 | Gerresheimer Wilden Ag Schweiz | Zahnbürste |

| US8881332B2 (en) | 2007-08-17 | 2014-11-11 | Lise W. Noble | Toothbrush system utilizing oral care capsule |

| US8156599B2 (en) * | 2007-10-03 | 2012-04-17 | Colgate-Palmolive Company | Oral care implement having a head insert |

| US8632268B2 (en) | 2008-05-06 | 2014-01-21 | Colgate-Palmolive Company | Implement having a reaction and delivery system |

| WO2009149569A1 (fr) * | 2008-06-14 | 2009-12-17 | Werner Hiltmann | Brosse |

| AU2014202126B2 (en) * | 2008-06-25 | 2016-03-03 | Colgate-Palmolive Company | Oral care implement with channel from store to first and second face of the head |

| AU2012202440B2 (en) * | 2008-06-25 | 2014-01-16 | Colgate-Palmolive Company | Oral care implement with channel from store to first and second face of the head |

| RU2550429C2 (ru) | 2008-12-30 | 2015-05-10 | Конинклейке Филипс Электроникс, Н.В. | Зубная чистящая капа с разными секциями щетинок для разных зубных областей |

| USD660599S1 (en) * | 2009-02-05 | 2012-05-29 | Colgate-Palmolive Company | Toothbrush |

| US8113729B2 (en) * | 2009-07-08 | 2012-02-14 | Dental Development Systems, Llc | Toothpaste droplets |

| WO2011025810A1 (fr) * | 2009-08-26 | 2011-03-03 | Gmz Associates, Ltd | Brosse à dents écologique |

| US8529150B2 (en) | 2009-09-23 | 2013-09-10 | Richard Carl Olson | Toothbrush device |

| USD632484S1 (en) | 2009-12-18 | 2011-02-15 | Eduardo Jimenez | Toothbrush handle with tissue cleaner |

| USD654270S1 (en) | 2009-12-18 | 2012-02-21 | Colgate-Palmolive Company | Toothbrush handle |

| USD654696S1 (en) | 2009-12-18 | 2012-02-28 | Colgate-Palmolive Company | Toothbrush handle with tissue cleaner |

| USD675830S1 (en) | 2009-12-18 | 2013-02-12 | Colgate-Palmolive Company | Toothbrush |

| USD654695S1 (en) | 2009-12-18 | 2012-02-28 | Colgate-Palmolive Company | Toothbrush |

| US8500766B2 (en) | 2009-12-18 | 2013-08-06 | Colgate-Palmolive Company | Oral care implement multiple soft tissue cleaner components |

| MX2012010401A (es) * | 2010-03-31 | 2012-10-03 | Colgate Palmolive Co | Dispositivo para el cuidado oral. |

| EP2604141B1 (fr) * | 2010-08-12 | 2018-12-05 | Mitsubishi Pencil Company, Limited | Outil d'application |

| US9510667B2 (en) * | 2010-08-16 | 2016-12-06 | Theg, Inc. | Disposable toothbrush |

| US20120055497A1 (en) * | 2010-09-03 | 2012-03-08 | Marni Markell Hurwitz | Oral hygiene implement and method of use |

| ES2536848T3 (es) * | 2010-11-12 | 2015-05-29 | Dental Care Innovation Gmbh | Sistema de limpieza dental |

| EP2651776B1 (fr) | 2010-12-15 | 2015-05-06 | Colgate-Palmolive Company | Coffret de soins d'hygiène buccale et distributeur destiné à être utilisé avec celui-ci |

| AU2010365770B2 (en) * | 2010-12-22 | 2015-04-09 | Colgate-Palmolive Company | Oral care kit |

| EP3539417B1 (fr) * | 2011-01-04 | 2021-03-03 | Trisa Holding AG | Brosse à dents pourvue de soies moulées par injection |

| EP2848156B1 (fr) | 2011-03-28 | 2016-05-18 | Colgate-Palmolive Company | Brosse à dents à distribution de fluide pour soins buccaux |

| RU2013150865A (ru) | 2011-04-15 | 2015-05-20 | Колгейт-Палмолив Компани | Набор для ухода за полостью рта |

| US20120272468A1 (en) * | 2011-04-26 | 2012-11-01 | The Procter & Gamble Company | Oral Care Device Comprising A Synthetic Polymer Derived From A Renewable Resource And Methods Of Producing Said Device |

| US9510668B2 (en) * | 2011-04-29 | 2016-12-06 | Colgate-Palmolive Company | Oral care implement having visual indicator of depletion of a fluid |

| US9510664B2 (en) | 2011-11-22 | 2016-12-06 | The Procter & Gamble Co | Toothbrush having an inner cavity |

| US9463593B2 (en) | 2011-11-22 | 2016-10-11 | The Procter & Gamble Company | Method for producing a toothbrush having an inner cavity |

| WO2013078356A2 (fr) | 2011-11-22 | 2013-05-30 | The Gillette Company | Brosse à dents pourvue d'une cavité interne |

| US9756931B2 (en) | 2011-11-22 | 2017-09-12 | The Procter & Gamble Company | Method for producing a toothbrush having an inner cavity |

| US9420877B2 (en) | 2011-11-22 | 2016-08-23 | The Procter & Gamble Company | Method for producing a toothbrush having an inner cavity |

| US20130000659A1 (en) * | 2011-12-01 | 2013-01-03 | Davis John J | Toothbrush/toothpaste fluoride dosing toothbrush, system and method |

| DE102011122106A1 (de) * | 2011-12-22 | 2013-06-27 | Carl Freudenberg Kg | Besenblock mit Borstenstruktur |

| AU2012371680B2 (en) | 2012-03-01 | 2015-03-05 | Colgate-Palmolive Company | Oral care implement |

| US20130266361A1 (en) * | 2012-04-09 | 2013-10-10 | Jeffrey A. Gilbert | Disposable Toothbrush Having an Internal Toothpaste Cartridge |

| EP2866610A1 (fr) | 2012-07-02 | 2015-05-06 | Trisa Holding AG | Procédé de fabrication de brosses, notamment de brossettes interdentaires, et brosses, notamment brossettes interdentaires, et groupe de produits composés de plusieurs brosses |

| KR102046534B1 (ko) | 2013-01-25 | 2019-11-19 | 삼성전자주식회사 | 기판 가공 방법 |

| EP3057466B1 (fr) | 2013-11-05 | 2018-04-11 | Colgate-Palmolive Company | Accessoire pour soins buccaux |

| CN106572745B (zh) | 2014-07-30 | 2019-12-24 | 高露洁-棕榄公司 | 口腔护理器具和制造口腔护理器具的方法 |

| FR3024942B1 (fr) * | 2014-08-19 | 2016-08-19 | Oreal | Embout reservoir |

| CN106794057B (zh) * | 2014-09-29 | 2020-07-03 | 皇家飞利浦有限公司 | 具有无泵流体输送系统的口腔护理设备 |

| WO2016105372A1 (fr) * | 2014-12-23 | 2016-06-30 | Colgate-Palmolive Company | Accessoire de soins buccaux |

| DE102015105469A1 (de) * | 2015-04-10 | 2016-10-13 | Klemens Hanses | Toilettenbürste mit einem Reinigungsmittelbehälter |

| WO2017076839A1 (fr) | 2015-11-04 | 2017-05-11 | Trisa Holding Ag | Brosse de soin corporel, pourvue de soies fabriquées par moulage par injection |

| US9700127B2 (en) * | 2015-11-10 | 2017-07-11 | Dr. Bob's Ltd. | Toothbrush having tufted bristles and tongue brush bristles emanating from the same surface |

| US10165852B1 (en) * | 2016-04-05 | 2019-01-01 | William R. Christman | Teeth cleaning implement |

| CA3021605A1 (fr) | 2016-04-20 | 2017-10-26 | Trisa Holding Ag | Produit de type brosse et procede de fabrication |

| USD825741S1 (en) | 2016-12-15 | 2018-08-14 | Water Pik, Inc. | Oral irrigator handle |

| RU2715202C1 (ru) | 2016-12-20 | 2020-02-25 | Колгейт-Палмолив Компани | Устройство для подачи текучей среды и приспособление для личной гигиены, содержащее его |

| CN110087505B (zh) | 2016-12-20 | 2021-09-28 | 高露洁-棕榄公司 | 流体供应装置和包含该流体供应装置的个人护理器具 |

| CA3044283A1 (fr) | 2016-12-20 | 2018-06-28 | Colgate-Palmolive Company | Appareil d'alimentation en liquide et accessoire de soins personnels le contenant |

| US11000117B2 (en) | 2016-12-20 | 2021-05-11 | Colgate-Palmolive Company | Fluid dispensing implement having curly tube with vent openings |

| US11071854B2 (en) * | 2017-06-27 | 2021-07-27 | Colgate-Palmolive Company | Oral care implement |

| EP3470015B1 (fr) | 2017-10-11 | 2021-07-07 | Trisa Holding AG | Partie poignée de la brosse à dents électrique et brosse à dents électrique dotée d'une partie poignée de la brosse électrique et une brosse enfichable |

| DE102017220748A1 (de) * | 2017-11-21 | 2019-05-23 | M+C Schiffer Gmbh | Zahnbürste |

| US11103057B2 (en) | 2017-11-27 | 2021-08-31 | Colgate-Palmolive Company | Oral care implement |

| US10849419B2 (en) | 2018-03-08 | 2020-12-01 | Olson Ip Technologies, Inc. | Oral care device |

| US10674808B2 (en) | 2018-03-23 | 2020-06-09 | Colgate-Palmolive Company | Oral care implement and method of forming the same |

| US10849422B2 (en) | 2018-11-13 | 2020-12-01 | Colgate-Palmolive Company | Method of sanitizing a toothbrush |

| US11484112B2 (en) | 2018-11-13 | 2022-11-01 | Colgate-Palmolive Company | Method of whitening teeth |

| US10638832B1 (en) | 2018-11-13 | 2020-05-05 | Colgate-Palmolive Company | Fluid dispensing oral care implement |

| US11547204B2 (en) | 2018-11-27 | 2023-01-10 | Colgate-Palmolive Company | Oral care implement having a release component |

| RU2695822C1 (ru) * | 2018-12-12 | 2019-07-29 | Антон Петрович Усов | Зубная щетка |

| RU189491U1 (ru) * | 2018-12-17 | 2019-05-23 | Антон Петрович Усов | Зубная щетка |

| US10827824B1 (en) * | 2019-05-10 | 2020-11-10 | George S. Ferzli | Personal care brush with single dose dispenser |

| RU2706822C1 (ru) * | 2019-06-20 | 2019-11-21 | Антон Петрович Усов | Зубная щетка для ухода за полостью рта |

| US11051606B2 (en) | 2019-06-28 | 2021-07-06 | Colgate-Palmolive Company | Oral care implement and method of assembling the same |

| CN110353397A (zh) * | 2019-08-05 | 2019-10-22 | 慈溪赛嘉电子有限公司 | 牙刷 |

| GB2604462B (en) * | 2022-04-07 | 2023-06-28 | Ruka Hair Ltd | A selfcare brush |

Family Cites Families (40)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1060524A (en) * | 1911-04-13 | 1913-04-29 | Leonard F Wolfe | Blacking-brush. |

| US1797946A (en) * | 1930-01-08 | 1931-03-24 | Eichel Emil | Toothbrush |

| US1947720A (en) | 1931-04-09 | 1934-02-20 | Stanley V Laub | Toothbrush |

| US1947721A (en) * | 1931-12-30 | 1934-02-20 | Stanley V Laub | Toothbrush |

| US1944067A (en) * | 1932-11-04 | 1934-01-16 | Claude R Collins | Fountain toothbrush |

| US1995374A (en) * | 1934-04-23 | 1935-03-26 | James D Young | Dentifrice holding toothbrush |

| US2127794A (en) * | 1935-02-19 | 1938-08-23 | Wastman Gothard | Dispensing device |

| US2216333A (en) * | 1936-06-13 | 1940-10-01 | White | Antisepticized brush |

| GB491140A (en) * | 1938-02-14 | 1938-08-26 | Eric Leopold Hugo Cosby | Improvements in or relating to brushes |

| US2262982A (en) * | 1938-08-24 | 1941-11-18 | Frank E Wolcott | Toothbrush |

| US2260100A (en) * | 1940-05-27 | 1941-10-21 | Deitrich | Fountain applicator |

| US2778045A (en) * | 1952-10-31 | 1957-01-22 | Bly Isaiah | Dentifrice-containing capsules |

| US2739328A (en) * | 1955-01-12 | 1956-03-27 | Dorothy K Bernier | Soap brush |

| FR2554331A1 (fr) | 1983-11-03 | 1985-05-10 | Corgier Monique | Brosse a dents perfectionnee |

| FR2583625A1 (fr) | 1985-06-20 | 1986-12-26 | Barry Christian | Dispositif d'hygiene pour brosser les dents |

| WO1988001839A1 (fr) * | 1986-09-08 | 1988-03-24 | Ginebre Frederic | Brosse a dents |

| US5061106A (en) | 1988-03-08 | 1991-10-29 | Colgate-Palmolive Company | Toothbrush with slow release of disinfectant and antibacterial agents and method of manufacturing the same |

| FR2629989A1 (fr) | 1988-04-15 | 1989-10-20 | Camara Naby | Brosse a dent a alveole garnie |

| BE1001993A7 (fr) * | 1988-05-24 | 1990-05-15 | Desmedt Robert | Brosse a dents a usage unique dentifrice incorpore. |

| US5066155A (en) * | 1988-08-29 | 1991-11-19 | English Philip H | Toothbrush and paste dispenser |

| FR2646068A1 (fr) * | 1989-04-19 | 1990-10-26 | Louin Patrice | Brosse a dents jetable a pastilles-dentifrice incorporees |

| US5181531A (en) * | 1991-07-18 | 1993-01-26 | Dario Escoto | Tooth cleaning kit for vending machines |

| US5346324A (en) | 1991-09-19 | 1994-09-13 | Youti Kuo | Dentifrice dispensing toothbrush with replaceable cartridge |

| IT1261302B (it) * | 1992-02-07 | 1996-05-14 | Spazzolino da denti | |

| US5392482A (en) * | 1993-11-26 | 1995-02-28 | Drulias; Dean | Disposable toothbrush |

| NL9400631A (nl) * | 1994-04-20 | 1995-12-01 | Wilhelmina Walthera Johanna Co | Tandenborstel, bestaande uit houder en borsteldeel. |

| US5490530A (en) | 1994-05-03 | 1996-02-13 | Snowden; Patricia | Disposable toothcare assembly |

| ITMI952073A1 (it) * | 1995-10-12 | 1997-04-12 | Vittorio Quattrocolo | Dispositivo per la pulizia dentale del tipo usa e getta |

| GB2323026B (en) | 1997-03-12 | 2001-05-09 | Wisdom Toothbrushes Ltd | Colour-changing wear-indicating filaments |

| US5909977A (en) | 1997-03-31 | 1999-06-08 | Kuo; Youti | Dentifrice dispensing toothbrush with refillable cartridge |

| US5865195A (en) * | 1997-07-03 | 1999-02-02 | Carter; Theresa | Oral hygiene system |

| DE29718117U1 (de) * | 1997-10-13 | 1998-01-22 | Ott Michael | Toilettenbürste mit extra 75 cm langem Stil und auswechselbarem, perforiertem Bürstenkopf, in den eine Reinigungs-Desinfektionspatrone eingeführt werden kann |

| GB2375040B (en) * | 1998-10-07 | 2003-04-09 | Christina Elsender | Disposable reservoir toothbrush |

| CA2364109A1 (fr) | 1999-03-10 | 2000-09-14 | Bruce Alan Sargent | Brosse a dents jetable |

| DE10013495B4 (de) * | 2000-03-20 | 2004-01-29 | Klemens Hanses | Toilettenbürste |

| EP1190643A1 (fr) * | 2000-09-20 | 2002-03-27 | Givaudan SA | Dispositif pour appliquer une matière active sur une surface et récipient contenant une dose unique de matière active |

| ITMI20010045U1 (it) | 2001-01-26 | 2002-07-26 | Vanni Calligaro | Spazzolino da denti perfezionato |

| US6602013B2 (en) * | 2001-08-27 | 2003-08-05 | Frank Clark | Chewable toothbrush |

| EP2537436B1 (fr) | 2002-09-05 | 2015-04-01 | Colgate-Palmolive Company | Brosse à dents jetable |

| US7331731B2 (en) * | 2002-09-05 | 2008-02-19 | Colgate-Palmolive Company | Oral care toothbrush |

-

2004

- 2004-09-22 EP EP20040022614 patent/EP1639913B1/fr active Active

- 2004-09-22 AT AT04022614T patent/ATE534314T1/de active

-

2005

- 2005-09-07 EP EP15187837.8A patent/EP3000351B1/fr active Active

- 2005-09-07 EP EP10011705.0A patent/EP2335521B1/fr not_active Not-in-force

- 2005-09-07 EP EP05785195.8A patent/EP1796507B1/fr not_active Not-in-force

- 2005-09-07 WO PCT/EP2005/009615 patent/WO2006032367A1/fr active Application Filing

- 2005-09-07 US US11/662,486 patent/US8109686B2/en not_active Expired - Fee Related

-

2011

- 2011-12-30 US US13/341,212 patent/US8408833B2/en active Active

-

2013

- 2013-02-27 US US13/779,032 patent/US8851781B2/en active Active

-

2014

- 2014-08-13 US US14/458,710 patent/US9538837B2/en active Active

-

2016

- 2016-12-07 US US15/371,578 patent/US10390606B2/en active Active

-

2019

- 2019-06-19 US US16/445,757 patent/US10856647B2/en active Active

Cited By (24)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US8806695B2 (en) | 2002-08-09 | 2014-08-19 | Colgate-Palmolive Company | Oral care implement having flexibly supported cleaning elements extending in opposite directions |

| US9167888B2 (en) | 2002-08-09 | 2015-10-27 | Colgate-Palmolive Company | Oral care implement having flexibly supported cleaning elements extending in opposite directions |

| US8449211B2 (en) | 2002-09-05 | 2013-05-28 | Colgate-Palmolive Company | Oral care toothbrush |

| US8764332B2 (en) | 2002-09-05 | 2014-07-01 | Colgate-Palmolive Company | Oral care toothbrush |

| US9265337B2 (en) | 2002-09-05 | 2016-02-23 | Colgate-Palmolive Company | Oral care toothbrush |

| US8240937B2 (en) | 2002-09-05 | 2012-08-14 | Colgate-Palmolive Company | Oral care implement with bead retention |

| US9167886B2 (en) | 2007-01-24 | 2015-10-27 | Colgate-Palmolive Company | Oral care implement having fluid delivery system |

| US8517728B2 (en) | 2007-01-24 | 2013-08-27 | Colgate-Palmolive Company | Oral care implement having fluid delivery system |

| US8920168B2 (en) | 2007-01-24 | 2014-12-30 | Colgate-Palmolive Company | Oral care implement having fluid delivery system |

| CN104095391B (zh) * | 2007-02-22 | 2016-08-17 | 高露洁-棕榄公司 | 牙刷 |

| US9398940B2 (en) | 2008-06-04 | 2016-07-26 | Colgate-Palmolive Company | Oral care implement with cavitation system |

| US8747005B2 (en) | 2008-06-04 | 2014-06-10 | Colgate-Palmolive Company | Oral care implement with cavitation system |

| RU2465797C2 (ru) * | 2008-06-25 | 2012-11-10 | Колгейт-Палмолив Компани | Инструмент для ухода за полостью рта (варианты) |

| US9131767B2 (en) | 2008-06-25 | 2015-09-15 | Colgate-Palmolive Company | Oral care implement |

| US8459892B2 (en) | 2008-06-25 | 2013-06-11 | Colgate-Palmolive Company | Oral care implement |

| US8628264B2 (en) | 2008-06-26 | 2014-01-14 | Colgate-Palmolive Company | Oral care implement |

| US9149110B2 (en) | 2008-06-26 | 2015-10-06 | Colgate-Palmolive Company | Oral care implement |

| US8282298B2 (en) | 2008-06-26 | 2012-10-09 | Colgate-Palmolive Company | Oral care implement |

| US8506196B2 (en) | 2010-02-26 | 2013-08-13 | Colgate-Palmolive Company | Fluid delivery system for an oral care implement |

| US9237798B2 (en) | 2010-03-04 | 2016-01-19 | Colgate-Palmolive Company | Fluid dispensing oral care implement |

| US8398326B2 (en) | 2010-03-04 | 2013-03-19 | Colgate-Palmolive Company | Fluid dispensing oral care implement |

| US8734042B2 (en) | 2010-03-31 | 2014-05-27 | Colgate-Palmolive Company | Oral care implement with rapid flavor release |

| US9402700B2 (en) | 2011-03-09 | 2016-08-02 | Colgate-Palmolive Company | Interdental cleaning device |

| US9554641B2 (en) | 2012-10-26 | 2017-01-31 | Colgate-Palmolive Company | Oral care implement |

Also Published As

| Publication number | Publication date |

|---|---|

| US20190357666A1 (en) | 2019-11-28 |

| EP1796507A1 (fr) | 2007-06-20 |

| EP2335521B1 (fr) | 2015-12-16 |

| EP1796507B1 (fr) | 2013-10-23 |

| EP3000351B1 (fr) | 2020-02-12 |

| US8408833B2 (en) | 2013-04-02 |

| US9538837B2 (en) | 2017-01-10 |

| US20140348569A1 (en) | 2014-11-27 |

| US20130212823A1 (en) | 2013-08-22 |

| EP2335521A1 (fr) | 2011-06-22 |

| US20080014010A1 (en) | 2008-01-17 |

| US8109686B2 (en) | 2012-02-07 |

| US20170079420A1 (en) | 2017-03-23 |

| US20120121312A1 (en) | 2012-05-17 |

| US10390606B2 (en) | 2019-08-27 |

| US8851781B2 (en) | 2014-10-07 |

| ATE534314T1 (de) | 2011-12-15 |

| WO2006032367A1 (fr) | 2006-03-30 |

| EP1639913A1 (fr) | 2006-03-29 |

| US10856647B2 (en) | 2020-12-08 |

| EP3000351A1 (fr) | 2016-03-30 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1639913B1 (fr) | Brosse, notamment brosse à dents et procédé de fabrication | |

| EP3445205B1 (fr) | Produit de type brosse | |

| EP2343018B1 (fr) | Outil de protection orale | |

| EP2986248B1 (fr) | Porte-fil dentaire | |

| EP1220626B1 (fr) | Brosse, notamment brosse a dents | |

| EP3370567A1 (fr) | Brosse de soin corporel, pourvue de soies fabriquées par moulage par injection | |

| EP3539417A1 (fr) | Brosse à dents pourvue de soies moulées par injection | |

| KR20120130009A (ko) | 구강 관리 기구를 위한 유체 배출 시스템 | |

| EP2670278A1 (fr) | Pinceau doseur pour application locale ciblée | |

| AU2022252745A1 (en) | Fluid dispensing oral care implement | |

| EP3684221A1 (fr) | Dispositif applicateur | |

| CH712546A2 (de) | Mundhygienemittel. | |

| AU2011224060A1 (en) | Oral care implement | |

| AU2014268187A1 (en) | Oral care implement |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL HR LT LV MK |

|

| 17P | Request for examination filed |

Effective date: 20060830 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PL PT RO SE SI SK TR |

|

| 17Q | First examination report despatched |

Effective date: 20070321 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502004013082 Country of ref document: DE Effective date: 20120202 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: VDEP Effective date: 20111123 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |